Everything you need to know before investing in coding and labelling technology.

The demands of a label and code are ever changing. Gone are the days where codes were solely used for product identification. Now codes are being used to fight counterfeiters and build trust with consumers. Labels once only used for marketing and promotions now carry a treasure-trove of information as laid down by industry and retailer standards.

At the same time, coding and labelling technology has advanced to meet the pressure for better efficiency on the production line. Just like other packaging and processing machinery, coders and labellers are being scrutinised for their ability to maximise productivity, reduce operational costs, improve business growth, adapt with the ever-changing environment and ultimately create a lean organisation.

This guide will take you through the essential elements of coding and labelling. From the technology available and the terminology used, to best practices and the questions you should ask, it's here.

There’s a range of reasons you may use coding and labelling technology in your business to improve traceability, build long-lasting consumer relationships, drive sales, fight counterfeiters… the list goes on.

Here are just a few of the most important ways you can use coding and labelling technology:

In its most basic form, coding and labelling technology is used to apply some sort of identifying mark or code to a product through manufacturing or your supply chain.

This could be a date code to identify a best before or use by date, a unique combination of numbers and/or letters that signifies a batch, primary or product barcodes to identify the product at the retail point of sale, or even a carton or pallet label to identify a group of products.

Primary barcodes are generally included within the artwork used for the retail packaging and are pre-printed on the packaging or labels, whereas trade unit barcodes (TUN) are often printed and applied at the time of manufacture.

The global anti-counterfeit packaging market size is projected to grow from USD 106.3 billion in 2020 to USD 188.2 billion by 2025. Some sectors are more at risk than others. For example, potential losses to the global wine industry due to counterfeits are estimated to reach $4.3 trillion by 2022.

However, with the right coding and labelling technology, brand owners can make it more difficult for counterfeiters to break into the supply chain, namely by assisting in the identification, authentication and tracking of products.

Track-and-trace solutions enable items to be traced through the supply chain all the way to the consumer.

Barcode-enabled product tracking is one of the most common methods, with coding and labelling technologies making this easy to implement in a production or packaging line. This is also an effective way to ensure your products, not the counterfeits, are what consumers are buying. Track-and-trace can also assist in the tracking of withdrawals and recalls.

Codes and labels are a powerful promotional vehicle to engage and connect with consumers. On-pack promotions are just one example of how marketers can boost short-term sales, generate brand loyalty and awareness, and reward consumers.

QR (Quick Response) codes can now be scanned directly through the camera app on most smartphones, and users no longer need to download a separate app. This makes it even easier for brands to communicate with consumers.

When added to food product labels, QR codes can be scanned by consumers to instantly access interactive and trustworthy online content, such as recipes, competitions and videos. And they take up very space on the label or packaging.

Today’s consumers want to know everything about products they are buying. At the same time, retailers are demanding a higher standard of product information before allowing the item on their shelves.

Coding and labelling technologies allow manufacturers to include the level of information demanded by consumers and retailers, while also meeting the relevant industry standards.

For example, ingredient lists, country of origin information and nutritional panels are essential for most packaged food products sold in Australia, and according to the Food Standards Code, this information must be legible for the end consumer.

Imagine your production line as one seamless, ultra-efficient process. Some coding and labelling systems can now be incorporated into other line technologies, which means your automated solutions work as one.

For example, the Matthews A-Series Label Printer Applicator features on-board software for seamless integration. All printer and applicator settings can be set externally using a portable device over Wi-Fi via Virtual Network Computing (VNC) .

Since the humble barcode appeared in the 1960s, the number of codes in the supply chain has multiplied. Today there are lots of different codes you can use on your products, each with their own set of rules. We won’t lie – it can be confusing!

To help, here are the codes every manufacturer should know:

In Australia, the Food Standards Code states that packaged foods with a shelf life of less than two years must have a use-by date on the primary packaging and a best-before date in most other cases.

Go to the FSANZ website for more information on date-coding requirements.

A batch number or lot number is critical for traceability. FSANZ says traceability is “the ability to track any food through all stages of production, processing and distribution (including importation and at retail).”

All packages with the same batch number are considered to be the same in all respects. For example, two packets of biscuits may have the same ingredients in the same quantities, but Packet A is produced on Monday and Packet B is produced on Tuesday, meaning the best before dates are different. As a result, Packet B must have a different batch number to Packet A.

The same would apply if any one ingredient were sourced from a different supplier or country of origin— even if the result looks, tastes and appears the same as every other packet of biscuits. If the consumer, retailer or manufacturer identifies a problem with a product, the batch code allows the product to be traced back to a specific batch.

Products with the same batch code can then be recalled or withdrawn from the supply chain. The smaller the batch, the less costly for the manufacturer and the less impact it will have on brand trust.

Find out more about batch codes on the FSANZ website.

Identification codes are used to trace a product through the supply chain. Identification codes may be in the form of barcodes or alphanumeric codes. They can be printed on labels that are affixed to the product or printed or engraved directly onto the product, e.g. with parts manufacturing, the advantage of directly adding identification codes ensures the code remains on the part even if a label is lost over time.

Identification codes can include information like:

The code can be read at each point in the manufacturing, assembly and testing processes to track the product's location and performance. The codes tell the manufacturer exactly where each product is in the factory, and when it exits the line.

To read these identification codes, an automated identification system integrated with software, such as Matthews iDSnet, can be used. This system can image the part, locate the identification code and look up the code in the system database. The software then updates the database with the current location of that individual part.

A barcode (or “bar code”) is a machine-readable image used to represent data. A barcode scanner decodes the image and sends the data back to a computer system where it’s interpreted and processed.

Barcodes can be used to identify:

Not all barcodes are the same, and different types of barcodes are needed for different applications. Here are three applications you should be familiar with:

1. Product: Also referred to as "primary barcodes". Primary barcodes are generally an EAN13 type and used at the retail point of sale, which is included in the artwork of the retail packaging. However, this space is changing across many sectors to include a two-dimensional (2D) code capable of embedding more data. The primary barcode traditionally was the product GTIN (Global Trade Item Number), a number that uniquely identifies the trade item globally. With the addition of the 2D barcode, suppliers can embed more data into the product barcodes, including (but not limited to) variable measure weight, batch numbers, manufacture dates or price information.

2. Carton: TUN (Trade Unit Number) barcodes are used on shipper cartons to identify a trade quantity of products being transported or distributed to a retail store that contain a number of the same product. These barcodes can be printed with your carton artwork, if you have a dedicated carton for each product or SKU you manufacture. Alternatively, you can use a generic carton with product-specific information printed and applied to the carton within your plant. Find out how to apply carton labels.

3. Pallet: A shipment can contain pallets or containers of mixed products or single products. These are also known as “logistics units”. A Serial Shipping Container Code (SSCC) is used to identify, manage and track the logistics unit throughout its lifetime in the warehousing, distribution and transport process. An SSCC is typically represented in a GS1-128 barcode.

Find out everything you need to know about barcodes in our Barcode Learning Centre.

QR codes are two-dimensional computer-generated images that can be scanned by smartphones or tablets to generate an action. Created in Japan over 20 years ago to help manufacturing lines in the automotive industry, they are now almost exclusively used by brands to communicate with consumers.

Simply aim a smartphone camera at the QR code, software decodes it and connects you to the relevant webpage.

Learn more about 2D codes and why they remain relevant in 2020.

Another more traditional type of promotional code is the alphanumeric code. Their most popular use is for temporary on-pack campaigns. This is not only extremely cost-effective, but it also makes it easy to track results. A system such as Matthews iDSnet can generate and manage promotional codes as well as keep a record of what is printed.

Are you in the fresh produce industry? Find out the coding rules for fresh produce.

Once upon a time, there was only a handful of coding and labelling methods to choose from. Now there is something for practically every application, industry and product. There are four completely different types of inkjet technology alone!

Take time to understand the differences so you can choose the right one for your business.

Small character continuous inkjet (CIJ): A non-contact printing method where electrically charged droplets of ink are expelled from a printhead nozzle at up to 120,000 droplets per second. Because the ink droplets are just half the diameter of a human hair, CIJ printing technology delivers fast, precise and reliable results.

Recommended for:

Not recommended for:

Printing barcodes onto products or secondary packaging. Barcode labels are the preferred method for applying barcodes to generic cartons in Australia.

There are four main types of large character inkjet coders:

Thermal inkjet coding (TIJ): Uses a cartridge containing an ink reservoir and a series of resistive elements. Each element is activated by an electrical current, which heats the ink in contact with the element. An ink droplet is formed and then ejected out of the faceplate nozzle precisely onto the substrate.

The time between each firing is only 100 millionths of a second and the technology has a throw distance of 1-6mm (depending on the print-head technology employed), meaning TIJ technology is extremely fast and will print exceptional quality, even at high line speeds.

Recommended for:

Not recommended for:

Wet environments or high vibration production lines.

.jpg)

Drop-on-demand (DOD) inkjet printers: Each printhead contains several individual valves (typically 7, 16 or 32) that print dots at regular intervals. Arranged in a single column, the valves open and close independently to form ink drops "on demand". As your product moves adjacent to the printhead, it results in printed characters.

DOD printers can use a wide variety of inks to mark many different substrates. They can make low to medium resolution marks over heights ranging from 2.5mm to 128mm, or even higher when print-heads are linked together.

Recommended for:

Not recommended for:

Most retail packaging, due to their lower printing resolution.

High-resolution inkjet printers: The latest generation uses piezoelectric technology to create super-crisp images, with print heights up to 100mm from a single printhead; these can also be stacked together to achieve over 900mm. Ideal when you need the highest quality print on corrugated boxes and other porous materials.

Recommended for:

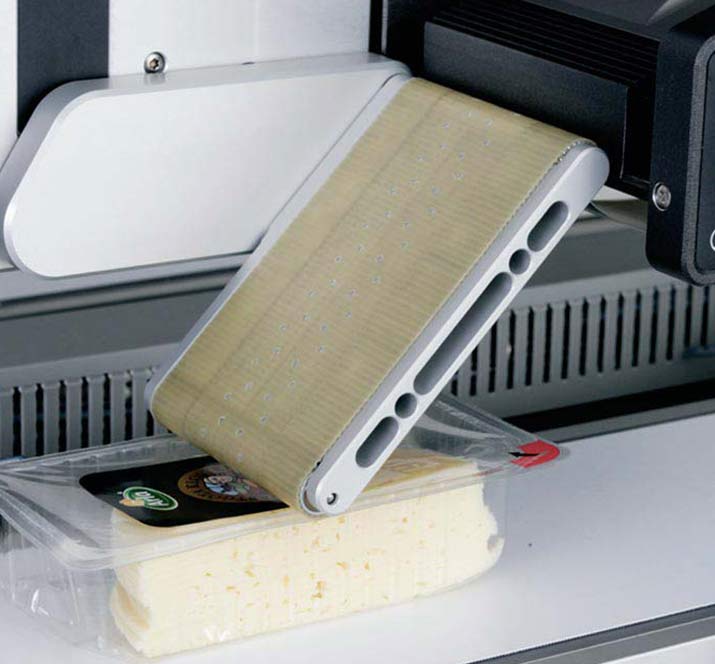

Thermal Transfer Overprinters (TTOs) use a high-resolution thermal printhead, which melts a wax and/or resin-based ink from a very thin thermal transfer ribbon (or “foil”) coating onto the surface of your product.

By allowing you to print easily onto generic film packaging, TTOs are an extremely cost-effective printing solution.

Recommended for:

Not long ago, the laser was considered a specialist marking and coding solution, with a hefty price tag to match. Today, thanks to the rapid advances in technology, laser coding has not only become more cost-effective, but it's also now the number one choice for a wide range of applications across food, beverage and pharmaceutical packaging, right through to heavy industries.

Lasers can also now mark clear and legible barcodes on primary and secondary packaging.

There are two types of technology from which to choose, depending on your application and the substrate you're marking onto:

CO2 laser technology is the old-school method of laser marking. It uses a carbon dioxide gas mixture, which is electrically stimulated to produce a high efficiency, high-quality beam. They are the most widely used laser types because of the cost efficiency, low operation costs, low maintenance and lack of consumables.

CO2 laser coders are also extremely versatile and can be used to mark onto a broad range of materials at high line speeds, including paper, cardboard, foils, coated metals, plastics, wood, glass and more.

Fibre laser is the newer of the two types and comes with some extra advantages. As part of the solid state laser group, this laser technology produces a higher intensity laser which is ideally suited to metal engraving and high-contract plastic markings.

A major advantage of fibre lasers over CO2 lasers is they can mark flexible packaging material where no special laser field exists. In other words, the original field created for a small character inkjet code will often be sufficient. Because of the beam’s high stability, the fibre laser won’t perforate flexible films, such as those used for snack food and confectionary packaging. This is of tremendous benefit to the food and grocery industry.

Another advantage is this technology is completely maintenance free, even over thousands of working hours. With a fibre system, you can expect a life expectancy more than four times that of the standard CO2 laser tube technology. Laser technology already boasts a low total cost of ownership (TCO), and the extended extraction filter life decreases this even more. Fibre laser technology also doesn’t need factory air for cooling or marking-head cleaning.

Also known as in-line applicators, label applicators (LAs) are automated labelling systems that apply pre-printed pressure-sensitive labels onto products.

Without the print technology of Label Printer Applicators (LPAs), LAs tend to be the perfect cost-effective alternative to the manual “slap-and-ship”. LAs can be used to apply primary labels to all shapes and sizes to retail products, promotional or marketing labels onto pre-labelled retail packs, and more.

Recommended for:

If you’re looking to drive efficiencies on your line and print compliant labels onto your primary products, cartons or pallets, a Label Printer Applicator (LPA) is a sound option. Ongoing advances in technology have led to rugged, high-performing workhorses that are the smart choice in even the most demanding environments.

Unlike Label Applicators, which apply pre-printed pressure-sensitive labels, a Label Printer Applicator prints onto pressure-sensitive labels then automatically applies those labels to a product, using a pneumatic applicator.

Recommended for:

Another option is to print the labels using a label printer and apply them to the product manually. This ensures that labels are fully compliant and will scan every time, either at the point of manufacture of the point of dispatch. Choose from either mobile industrial or desktop label printers, both of which are designed to help manufacturers increase productivity and accuracy in the factory or warehouse.

Recommended for:

Ever found yourself confused with coding and labelling acronyms? Here are the acronyms every manufacturer needs to know.

Label Printer Applicators (LPAs) print information onto pressure-sensitive labels, then automatically apply those labels onto cartons, pallets and products. They are also known as “print and apply” solutions, because that’s what exactly they do.

If you have your labels ready to go, a Label Applicator (LA) is a cost-effective alternative to the manual “slap-and-ship”. Unlike LPAs, they don’t print the labels, rather, LAs are automated labelling systems that apply pre-printed pressure-sensitive labels onto cartons, trays and primary products.

Small Character Continuous Inkjet (CIJ) is a non-contact printing method. Electrically charged droplets of ink are expelled from a print-head nozzle at up to 120,000 droplets per second onto a substrate. Because the ink droplets are just half the diameter of a human hair, CIJ printing technology delivers precise and reliable results, at speed.

Large Character Drop on Demand (DOD) inkjet printers are great for more demanding industrial applications. They can mark low to moderate resolution, small to large characters onto a variety of substrates, including secondary packaging, timber, metal, concrete, plastics, foam and more. Each print-head contains several individual valves arranged in a single column. The valves are able to open and close independently to form ink drops “on demand”, which drop precisely onto the substrate as it moves adjacent to the print-head.

Thermal Transfer Overprinters (TTO) use a high-resolution thermal print-head that melts a wax or resin-based ink from a thin thermal transfer ribbon (“foil”) coating onto the product’s surface. The thermal transfer ribbon’s smooth and waxy surface creates less friction when coding onto packaging, resulting in a crisp, durable print. This means a thermal transfer barcode is highly resistant to any chemicals, humidity, UV, abrasion and climatic changes that product packaging may encounter along the supply chain.

Thermal Inkjet (TIJ) coders use a cartridge containing an ink reservoir and a series of resistive elements. Each element is activated by an electrical current, which then heats the ink to create an ink droplet. The droplet is ejected out of the faceplate nozzle and onto the substrate. TIJ technology is extremely fast and will print exceptional quality; the time between each firing is only 100 millionths of a second and the technology has a throw distance of 1-6mm (depending on the print-head used).

Some inkjet technologies, such as the Matthews Mperia V-Series, have exceptional print flexibility when it comes to large-size information. Print-heads can create character heights from 5mm to 128mm. To achieve large character marking, you can even stack print-heads on top of each other. This is ideal for large graphics, such as logos.

When it comes to choosing coding and labelling technology, it pays to be strategic. Only by doing your research and weighing up the pros and cons can you pick the right technology for your application and business goals, now and well into the future.

Consider these essential factors when investing in coding and labelling technology:

The equipment you choose will depend on the code or label you are printing. Take the time to outline what you need to print before you leap. Are you printing a use-by date on the primary packaging? Or batch codes on secondary packaging? Consider if there are multiple different message types and what they are.

Paper, cardboard, wet glass, plastic, wood, cloth… every material has different properties, which ultimately affect the way a code will be printed or a label attached.

For example, lasers are a popular choice for manufacturers in beverage, pharmaceutical and snack food sectors because they offer a fast way to print high quality, permanent codes on almost any substrate, such as glass, plastics, metal and cardboard.

The speed of your production line will determine the capability you need from your coder or labeller. Look for a coder or labeller that can match the speed without compromising quality and reliability. For example, continuous inkjet printers (CIJs) have the advantage of being able to mark clearly on all packaging substrates at all production speeds. They are also very easily integrated into a conveyor production line.

If you’re looking for a compact machine, consider one that is machined as one piece to provide a smaller footprint on the factory floor.

If you need to code or label more than one product, select a machine that enables you to swap and change between lines.

Dusty? Wet? Cold? Some manufacturing environments can be challenging for technology. Choose a coder or labeller built to withstand your environment to ensure you get longer use and greater reliability.

Consider the current technology in your factory, and how easy it will be to integrate the coder or labeller with minimum disruption to your production line. Work out which connections you need for your line. You might need your coder or labeller to connect directly to barcode scanners, weigh scales, keyboards and other peripheral devices.

There’s no sense in investing in a coding or labelling solution that doesn't meet your needs twelve months down the line. Are you expecting to grow? Will you be printing on different substrates? Will you be introducing new SKUs or printing different messages? Each of these will impact your future coding and labelling needs.

Give some thought to the costs of the coding or labelling solution: what is the purchase cost of the equipment, and what are the ongoing running costs for your business? Know the operating costs, such as training, maintenance, energy, materials, repair, parts, service, and so on.

Choose an equipment provider with local maintenance teams who have the skills and resources to install, service and fix the date coder should anything go wrong.

Finally, talk to your team and find out what they will be comfortable operating. They might require additional training, so find out what kind of support is offered by the equipment provider.

Australian manufacturers are under growing pressure to improve efficiency and lower costs. A large part of the solution lies in internally optimising processes and equipment, including your labelling and coding equipment.

Save money, increase your coding equipment’s performance and improve your workforce’s productivity by simply understanding the life-cycle costs associated with equipment ownership – the Total Cost of Ownership.

The TCO covers both visible and hidden expenses. It should be measured over a 3 to 5-year period.

Visible expenses for labelling and coding equipment, for example, would include:

By understanding the true cost of your labelling and coding equipment, you can take proactive steps to reduce the TCO and improve your bottom line.

A large factor in this is choosing the right equipment provider in the first place. For example, the right provider can regularly inspect and maintain the coder, labeller or inspection equipment, with fixed-price service contracts, and provide the proper operator training.

You also need to weigh up the coder’s capital cost versus its ongoing running cost – a low capital cost but high running cost is a hidden TCO.

How do you become more productive without sacrificing the quality of the products going out the door? The second you start compromising on quality and overlooking regulatory and compliance standards, you lose customers.

The good news? There are ways to improve productivity while maintaining your high quality and compliance. For example, by using vision technologies to automate quality control of your coding and labelling, you reduce the potential for human error, enable greater transparency throughout the process, and benefit from major cost savings thanks to reduced rework and more reliable product quality.

Manufacturers can spend a significant amount of time, energy and money in checking products manually, but vision inspection systems allow for checks to be done automatically and accurately.

Investing in or upgrading your product ID and inspection equipment is a proven way to streamline your existing processes and improve efficiency.

How can you know where to improve efficiency if you haven’t got visibility of your production line? Overall Equipment Effectiveness (OEE) is a best practice metric used by many manufacturers to measure productivity.

OEE identifies the percentage of planned production time that’s truly productive i.e. a score of 100% represents perfect production with no downtime. However, most manufacturing lines are only 60% productive, meaning there is massive room for improvement. (source)

OEE is a good metric for managers, but it can be a bit too abstract for employees. “TAED” is a better metric for operators, because it provides real-time, motivational goals:

To see where to improve, you can’t rely on guesswork — you need to put the procedures and technology in place to clearly see, measure and drive efficiency. Coding and labelling equipment can easily keep product count since it sits towards the end of the line to measure actual production count, while inspection systems can keep count of the rejects.

Toyota in Japan has proven that, to maximise the money you make in manufacturing, you need Total Productive Maintenance (TPM). In other words, you have to take care of your equipment so you can eliminate all unplanned downtime.

There are essentially two approaches to equipment maintenance:

Reacting to maintenance on an “as needed” basis has the attraction of flexibility. That is, until you find yourself unable to get the parts or labour you need within a profitable timeframe.

The “putting out fires” approach occupies valuable resources, as key staff or technicians are forced to make crisis management time in their day. Worse, when you do have to fix something, you are working on limited information. You have to order supplies, tools, and trained labourers when breakdown happens, leading to unpredictable downtimes. All the while your floor staff are idle, unable to do their jobs.

The lean approach is preventative maintenance. On a closely monitored line, you have more information about the condition of your equipment, so you can discover what’s causing the breakdowns or production stoppages more quickly. You can avoid the “grey” areas of assessment and dodge unnecessary equipment purchases with up-to-date, real-time information on hand.

It also means you can get to the root cause of quality problems by ensuring equipment competence. And when your product is coming off the line with first-pass quality assurance, you avoid the expense and hassle of rework.

Preventative maintenance is also a major factor in increasing the life of your line equipment. In fact, many Matthews’ customers have in-line printers on the field for 15 (or more) years—even though the expected life of most printers is 5-7 years.

Running an efficient manufacturing environment doesn’t just mean having cutting-edge technology; it relies on you managing reactive and preventative equipment maintenance effectively.

The best way to do this is to choose equipment providers who have local maintenance teams with the skills and resources to install, service and fix equipment — sooner rather than later.

After all, when we’re talking about the breakdown of coding and labelling equipment on the end of the line, no code means no product. So, the faster you can get your production line back up and running, the less impact to your bottom line.

That’s why it’s critical to choose a local equipment provider with reliable service and support capability.

A provider’s expertise on the ground when you need it means you avoid the stress, hassle and costs of excessive downtime. If your equipment needs a special part for repair, you won’t have to wait weeks for it to arrive from overseas – a local equipment provider should have it ready to go. And, as every manufacturer knows, every minute your equipment is down is another dent in your profit margin and potentially your company’s reputation, because you can’t meet your supply schedules.

It’s not all about costs and deadlines; it’s also a matter of having access to specialists who can build a relationship with your team, and who will understand your individual business needs and service requirements. Only a local technical support team can do this properly.

When it comes to the crunch, how do you know that your coding and labelling equipment provider will come through?

1. Response time:How quickly can they support you if a breakdown occurs? How quickly can someone reach your site? Does it take days or weeks?

2. First-time-fix rate: When the technician visits your site, do they resolve the issue the first time? Or does it take a few visits? Or (very annoyingly) do they leave, only for the equipment to fail again just a few days later?

3. Phone assistance: Do they have a 24/7 helpdesk to guide you through basic fault-finding, so you can get up and running quickly?

4. Operator training:Do they have a program to train your staff on how to use and maintain your equipment effectively? For coding equipment in particular, operator training is essential to reduce coding errors.

5. Spare part availability:Many breakdowns require a part or module replacement, but does the field technician carry adequate spare parts? Or will you have to wait (and suffer costly downtime while the delivery eventually comes through from overseas)?

Choosing a local labelling and coding equipment provider makes great business sense. You get access to a nationally located technical support team, who are on hand to provide professionally servicing and support.

Having this type of capability and specialist knowledge at your fingertips is a real benefit to Australian manufacturers, who are otherwise faced with the challenge of finding spare parts, managing lengthy delivery time-scales or the costs of air-freight for replacement parts.

Look for a local supplier who provides 24-hour support too, as this will save even more time, money and hassle if your equipment breaks down.

If you are ready to upgrade or are thinking about investing in coding and labelling machinery for the first time, our team is ready to help.

Matthews has helped many Australian manufacturers to successfully deploy the right coding and labelling technologies. We can work with you to pick the solution that will work best for your business and application.