Need to code your pallets? SSCC Labels are required for all pallets and units that are used as a logistics units - with the SSCC Label forming a crucial role in identifying each pallet or carton and its contents. Here’s everything you need to know about the pallet label requirements of using SSCCs.

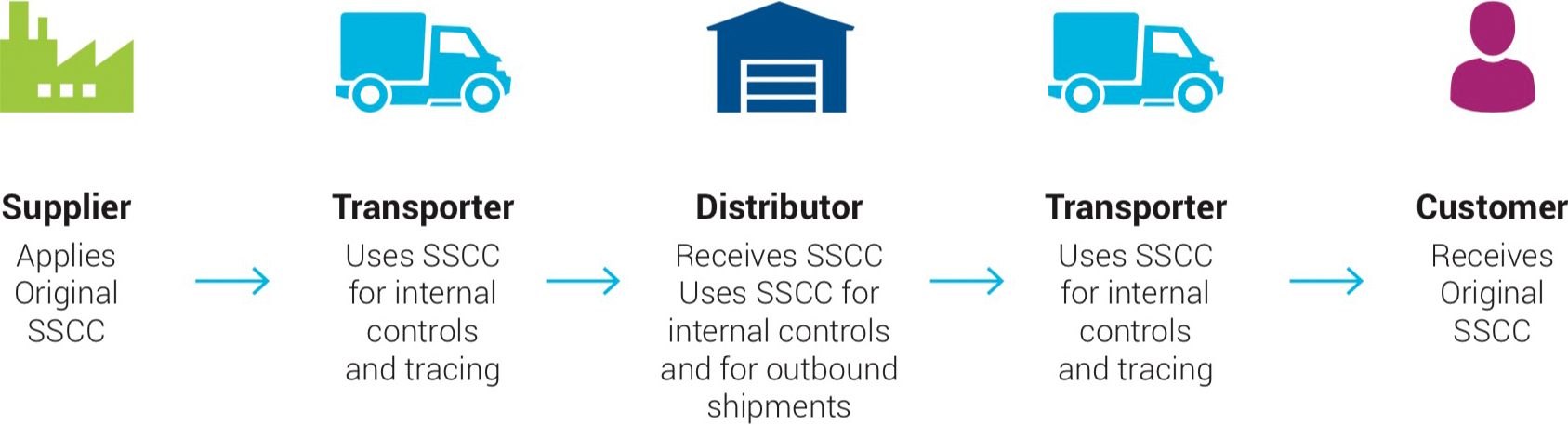

A Serial Shipping Container Code (SSCC) uniquely identifies an individual logistic unit, such as a pallet or case, from the sender to the final recipient.

Think of it as a number plate that uniquely identifies every car. The SSCC ensures the pallet’s movements can be individually tracked and traced throughout distribution and transport, all the way to the end receiver.

Retailers rely on SSCC labels to efficiently and accurately process inbound pallets. By scanning the SSCC on the pallet label, they can automate the receiving process and reduce human error and misidentification.

Transporting Pallets to Retailers: You already use barcodes for your products, now you need to transport pallets filled with products to the supermarket. Use an SSCC to identify each pallet. When the shipment arrives at the distribution centre, the SSCC is matched to the Despatch Advice, so the retailer can update their systems.

You are moving a load within a warehouse. Use an SSCC for internal pallet or unit identification.

SSCC pallet labels are required on all inbound deliveries across Woolworths, Coles and Metcash supply chain networks. With a high level of automation and high volumes of stock into the DCs, it is essential that all labels, including Coles SSCC and Woolworths SSCC, are in the right format, printed clearly and placed in the correct location on each pallet.

-min.jpg)

SSCC stands for Serialised Shipper Container Code.

The company putting together the logistics unit, such as a pallet, assigns the SSCC. GS1 Australia manages the standards for SSCC codes.

The date format for SSCC labels is YYMMDD. As this is a global standard this is a commonly recognised format.

Yes, but an individual SSCC cannot be reallocated within 12 months of the shipment date from the sender to a trading partner.

The SSCC refers to the individual code. The logistics label is the label applied to the logistics unit, such as a pallet or carton. The logistic label is often referred to as an SSCC label or pallet label because it must contain an SSCC.

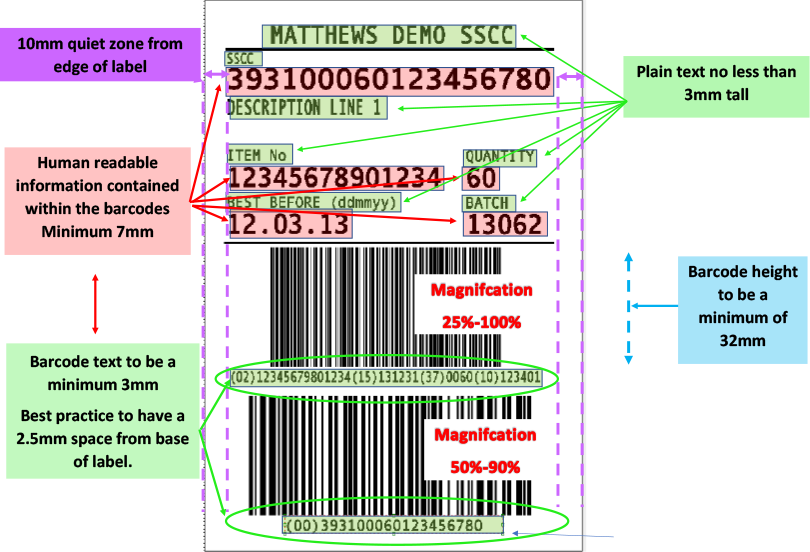

The SSCC is usually encoded in a GS1-128 barcode and is represented by the Application Identifier (AI) 00. You can also use a GS1 DataMatrix or QR Code with restrictions.

There are a number of vital steps to creating an SSCC code involving the Extension Digit, your GS1 Company Prefix and the Serial Reference number (assigned by you). To simplify this process we’ve created a new online SSCC tool that is FREE and easy to use: https://www.matthews.com.au/idsnet-cloud

The standard SSCC label is either A5 (148mm x 210mm) or A6 format (105mm x 148mm).

An SSCC label can be printed in either portrait or landscape formats and most warehouse label printers can handle either orientation. Choosing one or the other will dictate whether your barcodes are printed in ladder or picket fence directions (see our article on this discussion in the Barcode Learning Centre).

The shipper label should be placed either vertically above or below the SSCC label to avoid incorrect scanning and pallet rejects at automated DCs. Avoid placing the shipper barcodes horizontally inline with the SSCC barcodes.

A Quiet Zone (light margin) of 10mm should be maintained on both sides of the barcode symbols. If print extends into these light margins, scanners will struggle to identify the start and end of the barcode.

Using a 3PL logistics company means you may need to add 3PL or transport labels to get your pallets through the supply chain. Make sure these labels are placed ABOVE 800mm on your pallet and on the left-hand side of the pallet. This will ensure any barcodes on the 3PL or transport labels are not accidently scanned by the DC, and your pallets will be received first time, every time.

Australian-owned rice food product producer SunRice wanted to develop a solution that would efficiently mark and label their pallets and bulk bags with SSCC labels, while ensuring quality and correctness of all codes applied to their products. Our Matthews solution was to install Label Printer Applicators onto the palletising systems – these machines can effectively print and apply industry-approved SSCC labels. In addition, we implemented the package code management system, iDSnet software, which acts as a centralised point of control to reduce coding and labelling errors. Watch how SunRice is benefitting from improved efficiency and accuracy.

Whilst we attempt to update this page as changes occur we do not guarantee its accuracy and recommend that you contact GS1 Australia for the most up to date advice.