Choosing the right barcode for your product is an essential packaging step. It can be the difference between being sold on the shelves and being rejected by major retailers. There are two orientations to choose from – should you use a picket fence or a ladder barcode?

In this fact sheet, we discuss thermal transfer printing which is the standard technology used in most warehouse label printers. This is where barcodes are printed by using a series of tiny heated elements within the print head, causing sections of the label to turn black when heated.

This term refers to barcodes that are parallel to the movement of the label as it moves through the warehouse printer.

To combat the drawbacks of picket fence barcodes, we suggest printing a verification line before or after the barcode. The operator can then easily see if there is a problem, prior to printing too many codes. Alternatively, print varification technology will scan and check the barcodes for you.

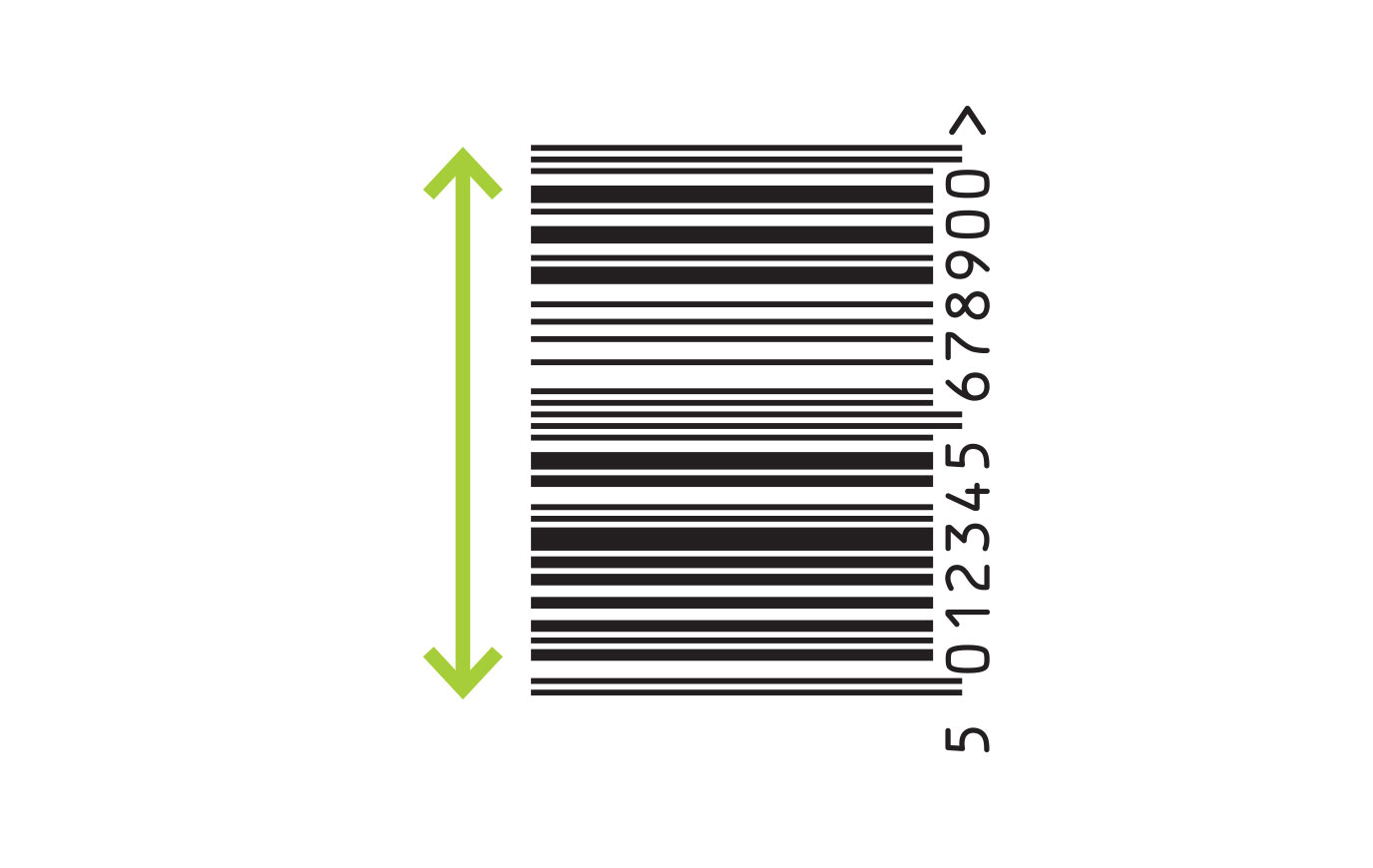

This refers to barcodes that are perpendicular to the direction of the label as it travels through the printer. They are typically used for small, cylindrical products, such as cans, where the code will be positioned vertically.

The Picket Fence barcode is our most highly recommended orientation – unless you are working with a small cylindrical product such as a canned fruits or bottled sauces. We’ve partnered with GS1 Australasia, so we can advise on the best option for your business.