BACKGROUND

Anika Natural Products toll manufactures a wide variety of natural and certified organic skincare products. Opening in 1995, the niche operator has grown around 35% per annum for the past few years. A carbon-neutral operator, Anika doesn’t produce its own branded line, keeping its “customer only” focus and accredited facilities as a commercial point of difference. The small family business produces for brands that export to the UK, Europe, America and parts of Asia, with one client about to launch into the Middle East.

SITUATION

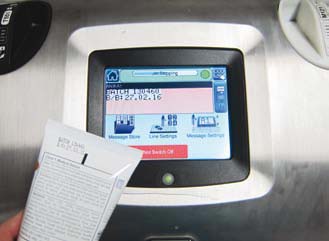

Anika invested in tube-sealing equipment to package a client’s newly launched product. While the ultrasonic tube-sealer has up-to-date technology, it could only code on one side of the tube’s end. However, Anika’s client legally needed coding on both sides of the crimped end.

PROCESS NEEDS

The coder needed to be able to fit into Anika’s existing production line, and work with the new tube sealer.

.png)

.png)

.png)

.png)