Feb 25, 2021 by Webmaster

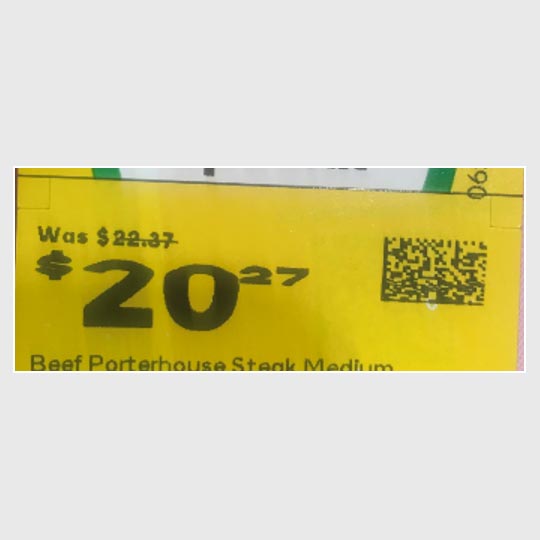

2D barcodes herald one of the largest changes to consumer packaging since the barcode was first introduced in the 1970s. Matthews have been working closely with Woolworths through the challenges of implementing such a major change. Being one of the first countries in the world to adapt to this level of data being embedded into a package code is an exciting journey for Australian manufacturers and suppliers. With this change, the retailer (in this example Woolworths) can ensure when a 2D code is scanned at the checkout that the product is within its date and if there is any reason for a recall it is easily identifiable down to a batch/package level.

In this article, we summarise our top six tips for suppliers looking to add data embedded codes to their product lines.

GS1 DataMatrix is a compact, two-dimensional barcode which holds a large amount of data in a small space. At its maximum, a DataMatrix symbol can store a large amount of alphanumeric characters, which may include manufacturer ID, a unique serial number and more.

The code is structured in a square or rectangular pattern. In the case of Woolworths GS1 Datamatrix all codes will be a square pattern (equal X and Y dimensions).

Check out the standards and learn as much as you can about identifiers relating to your industry and product range. For example, a Use By identifier (17) is different to a Best Before identifier (15) and this has impacts at a store level in terms of your product saleability. For a full list of GS1 Application Identifiers check out the GS1 website.

Code magnification (also known as your X dimension) is an important consideration and critical to get right for scanability. The X dimension for Woolworths is required to be between 0.625-0.9mm which is the most efficient decoding method for their scanners. Additionally on a curved product (such as a lamb shoulder) the scanner will fail at larger magnifications.

Ensure that your validation tools are fit for purpose. Just because your smart device scans the code, don’t assume the Point Of Sale scanners will too. Consider inline verification/code presence systems with inbuilt grading tools if you are unsure.

Key considerations relating to substrate are as follows:

The two most common printing technologies here are direct thermal and thermal transfer. Each has their own advantages and disadvantages to consider before making a selection.

What is Direct Transfer Labelling? This option uses no ribbon and provides a lower contrast. It may seem cheaper to choose the method that doesn’t require a ribbon, but ‘saving on ribbon costs’ is the wrong question to ask yourself when assessing this technology.

What is Thermal Transfer Labelling? Many are keen to avoid this method as it means avoiding the additional costs of the transfer ribbon. However, this option can result in a higher-quality barcode that stands the test of time.

"We’re pleased that so many of our suppliers can see the benefits of transitioning to 2DBarcodes. It's important for suppliers that are transitioning to 2DBarcodes to get in touch with their print partners early on in the process. This will help to smooth the transition and get the right quality product labels in store."

- Jennifer Keegan, Head of Support Portfolio Delivery, Woolworths Group.

We hope these tips were beneficial to you and your business as you begin your journey towards data embedded barcodes. To learn more about barcodes and packaging standards, check out our Barcode Learning Centre at the following link: https://www.matthews.com.au/barcode-standards