Apr 17, 2025 by Mark Dingley

Remember back in 2018 when Australia set its National Packaging Targets for 2025?

Well, 2025 is here, and businesses and industries are under pressure to meet their sustainability commitments.

So, where do we stand? And what’s next for sustainable packaging in Australia?

Let’s look at the policies, innovations and industry shifts shaping the future.

Woolworths’ Head of Packaging Bryan McKay giving his presentation on Sustainable Packaging as part of the Matthews-Australian Food & Grocery Council’s Retailer Engagement Hub at APPEX 2024.

How do regulations shape the future of packaging? Here’s an overview of the forces driving change.

Australia has set ambitious sustainability goals. The 2025 National Packaging Targets, led by the Australian Packaging Covenant Organisation (APCO), set clear objectives:

.jpg)

Above: The Australasian Recycling Label.

To make this happen, the government has introduced key policies:

However, in 2025, it’s clear that the goals remain out of reach.

That said, thereis some good news. Currently, 86% of all packaging in Australia can be recycled, which is a bit shy of the 100% target, according to figures released in December. Recycled content has reached 40%, compared with the 50% goal.

While paper, metal and glass are performing well, plastic remains a challenge. Only around 10% of plastic packaging contains recycled content, and 19% of plastic packaging is recycled – well below the 70% target.

Jennifer Macklin from Monash University’s Sustainable Development Institute said the goals were “ambitious”.

“If you think about taking the multitudes of different types of packaging – packaging on your household food and groceries from a supermarket, packaging on what businesses receive,or even packages in the health and medical sectors – it’s used across our entire economy.

“That's a huge shift to make in seven years to change how that packaging is designed [and] what it’s made from in order to be 100% recyclable.”

But this isn’t the end. APCO has unveiled a 2030 Strategic Plan, which includes financial incentives for members who incorporate sustainability into their packaging designs by using recycled content and the right materials.

At the same time, the Australian Government is ramping up regulation reforms to reduce waste, increase recycling ratesand foster a circular economy. For example, the Department of Climate Change, Energy, the Environment and Water (DCCEEW), has proposed banning, or phasing out, chemicals and materials that impede recyclability.

So what’s holding us back? The shift towards sustainable packaging isn’t just about swapping plastic for paper, it’s about rethinking materials, processes and the entire packaging lifecycle to create a circular economy.

While progress is happening, there are still significant roadblocks holding businesses and industries back:

Ultimately, overcoming these obstacles will require a coordinated approach, balancing cost, supply chain solutions and consumer education.

Looking overseas can provide clues on where Australia might be headed.

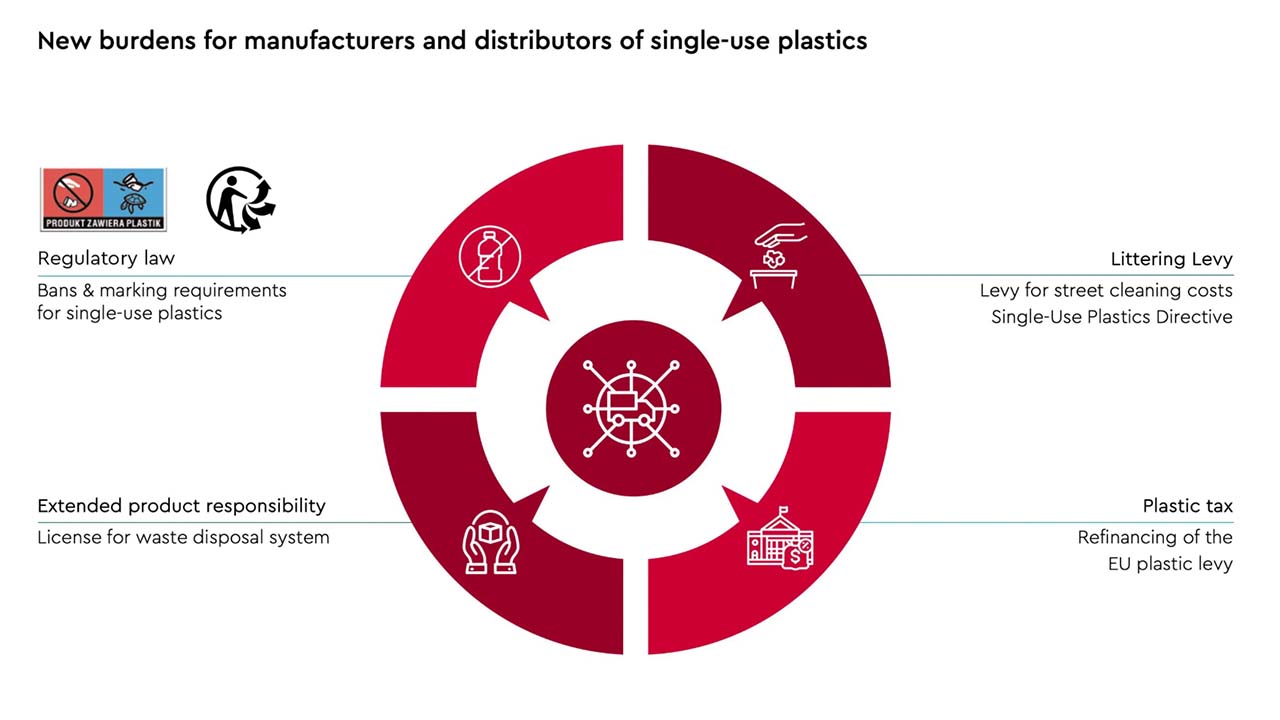

For instance, the European Union’s Packaging and Packaging Waste Regulation (PPWR) is setting strict targets for reusable and recyclable packaging. By 2030, transport packaging in the EU must hit a 40% reuse rate, climbing to 70% by 2040.

These EU laws also require importers of recycled materials to meet strict environmental standards, ensuring that cheaper, less sustainable imports don't undercut their local industries. Australia could follow suit to protect its recycling and packaging sector from similar challenges.

Additionally, the UK and EU have implemented a plastic levy based on the percentage of recycled content used in packaging. This is designed to encourage brands to use more recycled materials in packaging, discourage the use of virgin resin and stimulate the local circular economy.

Source: WTS Global

Necessity is the mother of invention, and innovation is driving sustainable-packaging solutions. These advancements are critical in overcoming current challenges and creating a true circular economy.

Here are some of the biggest trends in sustainable packaging:

.jpg)

Image source: https://aus.mars.com/news-and-stories/

How do these innovations play out in the real world? See how these seven brands are pioneering eco-friendly packaging.

Technology is driving big improvements in sustainability, reshaping how packaging is designed, used, and disposed of.

Unsurprisingly, one of the key technologies driving change is artificial intelligence. AI-powered design tools are helping brands test different materials and optimise packaging to reduce waste. Machine-learning algorithms are being used to analyse data to determine the most efficient use of packaging materials. For instance, these AI systems can optimise box sizes and material usage and predict performance metrics for different designs.

For example, an AI model created by Amazon called The Package Decision Engine is able to determine the most efficient type of packaging for each item it learns about, which helps reduce the number of cardboard boxes, air pillows, tape and mailers used to send purchases to customers.

Another technology making waves is blockchain. Brands can use blockchain to authenticate their environmental claims, for instance, by providing verifiable data on sourcing and processing of packaging materials. This transparency strengthens brand reputation and loyalty in a market increasingly wary of greenwashing.

Then there’s connected packaging. This offers a direct channel for brands to educate consumers on proper recycling or disposal methods while promoting the brand’s environmental efforts. By scanning QR codes on the packaging, consumers can instantly access sustainability information, recycling instructionsand interactive content about the environmental benefits of sustainable packaging.

For example, Mondelez is using on-pack QR codes to send customers to Snacking Right, a site that explains the company’s sustainability progress and how everyone can play a role in reducing their environmental impact. The site provides consumers with information about how to recycle, as well as stories about the dairy-farming families that supply fresh milk to the Cadbury brand.

There’s no one-size-fits-all solution to sustainable packaging. Different sectors require different approaches. The good news? Change is happening. Businesses are adopting more sustainable designs and materials, and innovations are emerging every day. Governments are reforming regulations, pushing industries toward circular economies.

The challenge now is scaling these solutions while keeping them cost-effective, practical, and consumer-friendly. Businesses must evaluate their packaging strategies, explore new materials, and stay ahead of regulatory changes.

Those who innovate now will lead tomorrow’s packaging landscape.

Looking for more inspiration for your sustainable packaging and other sustainability initiatives? Learn from these 9 sustainable Australian companies and check out these 5 incredible examples of sustainability x brand collaborations.