Oct 03, 2024 by Mark Dingley

When considering an upgrade of old production line equipment, such as inkjet printers, understanding the Bathtub Curve can help you make more informed decisions.

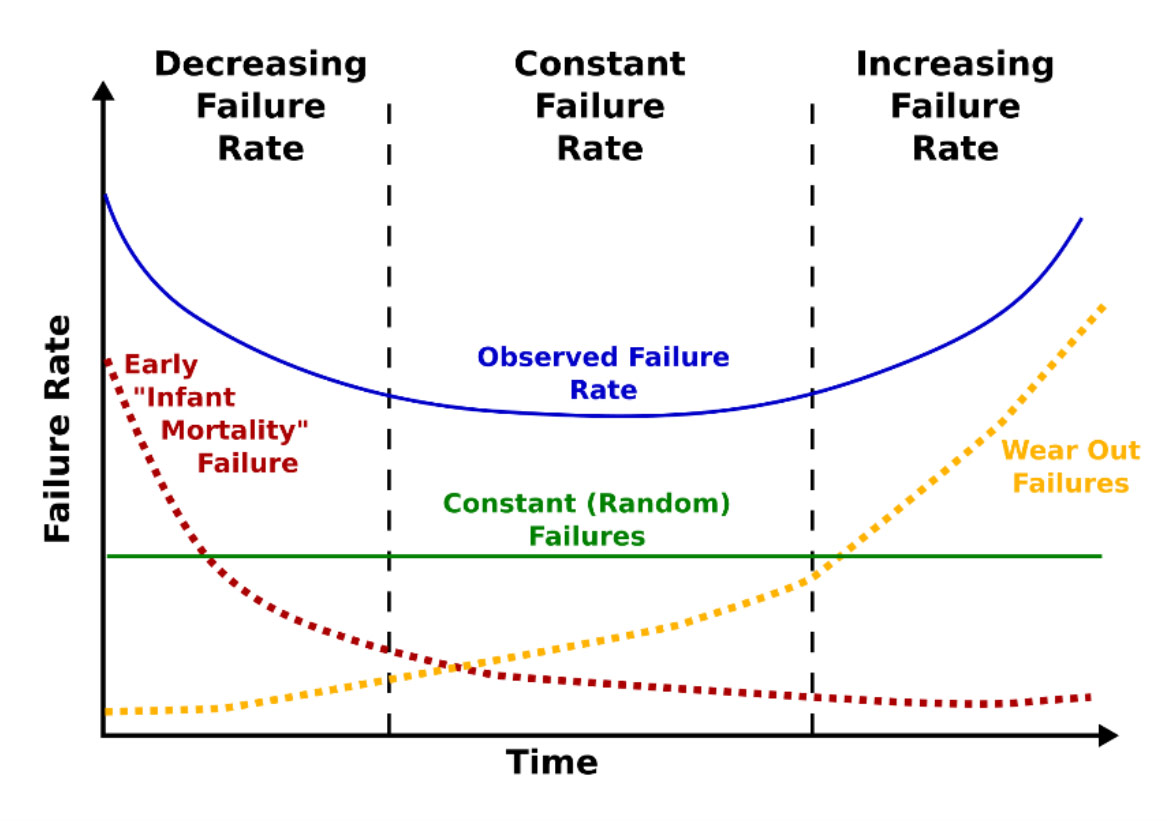

The Bathtub Curve is a widely used concept in reliability engineering, particularly for electromechanical equipment, which includes everything from motors and conveyors to coding and marking systems like inkjet printers. It describes the typical failure rates over a product's life cycle and applies to all products in this category, not just printers.

The Bathtub Curve visually represents the three distinct phases in the life cycle of a piece of equipment: the early failure phase, the useful life phase, and the wear-out phase. This curve gets its name from its shape—early failures create a steep drop, followed by a flat line during the machine’s stable performance, and finally a sharp rise as the equipment begins to wear out.

For inkjet printers used in production environments, the wear-out phase introduces serious reliability risks, as critical components degrade over time. As your equipment approaches this phase, not only does the risk of unexpected downtime increase, but so do the associated costs. For many manufacturers, an hour of downtime can cost upwards of $10,000 or more, depending on the scale of the operation. When factoring in labor costs, lost production, and missed deadlines, even a few minutes of unplanned downtime can have a significant financial impact.

When new production line equipment is installed, there is often a brief period known as the early failure or "burn-in" phase, where failures may be more frequent as components settle in or installation errors are identified. This is more common with newly engineered or innovative technologies, where initial failures may occur as the equipment stabilises. However, for many types of industrial equipment, including continuous inkjet printers, these early-stage issues have become less common due to advances in design, diagnostics, and robust manufacturing standards.

While new equipment often comes with warranties and support to cover this initial period, it’s important to note that reliability has improved significantly across the board. Most equipment is expected to integrate smoothly into production lines with minimal disruption. For those considering trading in old printers or other machinery, concerns about early failures are less relevant today, thanks to these advancements in technology, offering a smoother and more reliable transition.

The middle of the Bathtub Curve represents the useful life phase, where failure rates are low and the equipment operates as expected. This is the ideal period for production line inkjet printers, offering peak reliability, high performance, and consistent uptime. For well-maintained equipment, this phase can last several years, ensuring stable and predictable output.

However, as your inkjet printer ages and approaches the end of this phase, the risk of low-quality prints or illegible date codes increases, which can lead to severe consequences. Poor-quality prints can result in product recalls, regulatory non-compliance, or damage to your brand’s reputation—especially in industries like food and beverage, where traceability and accurate coding are critical. The cost of a product recall, including logistics, brand impact, and lost sales, can far outweigh the investment in new equipment.

As equipment moves into the wear-out phase, the rate of failures increases sharply. Components such as printheads, power supplies, and moving parts deteriorate due to prolonged use, leading to frequent breakdowns. Maintenance costs also escalate as more time and resources are spent trying to keep aging machines operational. For inkjet printers, common issues include clogged nozzles, ink leaks, and calibration errors, which directly affect the quality of your product labeling and coding.

In the wear-out phase, your operation is more vulnerable to unplanned downtime and inconsistent output, and the financial costs can skyrocket. Consider this: even 10 minutes of downtime could cost your business several thousand dollars in lost production, delayed orders, and overtime labor to catch up. Additionally, fines for non-compliance with product labeling standards can add further to the cost.

Continuing to operate in this phase not only impacts your efficiency but also poses a risk to product quality, customer trust, and long-term profitability. Upgrading to a new printer before these issues intensify allows you to avoid the growing risks associated with aging equipment and maintain consistent production output.

.jpg)

Understanding the Bathtub Curve helps you anticipate when your aging electromechanical equipment—such as inkjet printers—might begin to fail more frequently. By recognising the signs of wear and knowing when your equipment has moved beyond its useful life, you can take proactive steps to avoid costly downtime and protect your business from the risk of product recalls and brand reputation damage.

When one considers the increased risks and costs associated with the wear-out phase, in tandem with the relative cost of replacing printers, it seldom makes sense to persist with older printers into this phase. Matthews now makes it even more attractive to upgrade your printers at this stage with our limited-time trade-in offer, helping you save up to $3,590 and secure next-day budget pricing.

Don’t wait until your printer fails—upgrade now and maintain high-quality, reliable performance for years to come.