Apr 19, 2024 by Mark Dingley

Are you getting ready to supply to an automated distribution centre (DC)?

With Coles, Woolworths and Metcash investing in automated DCs, it's never been more important for suppliers to ensure that their products and pallets meet the requirements.

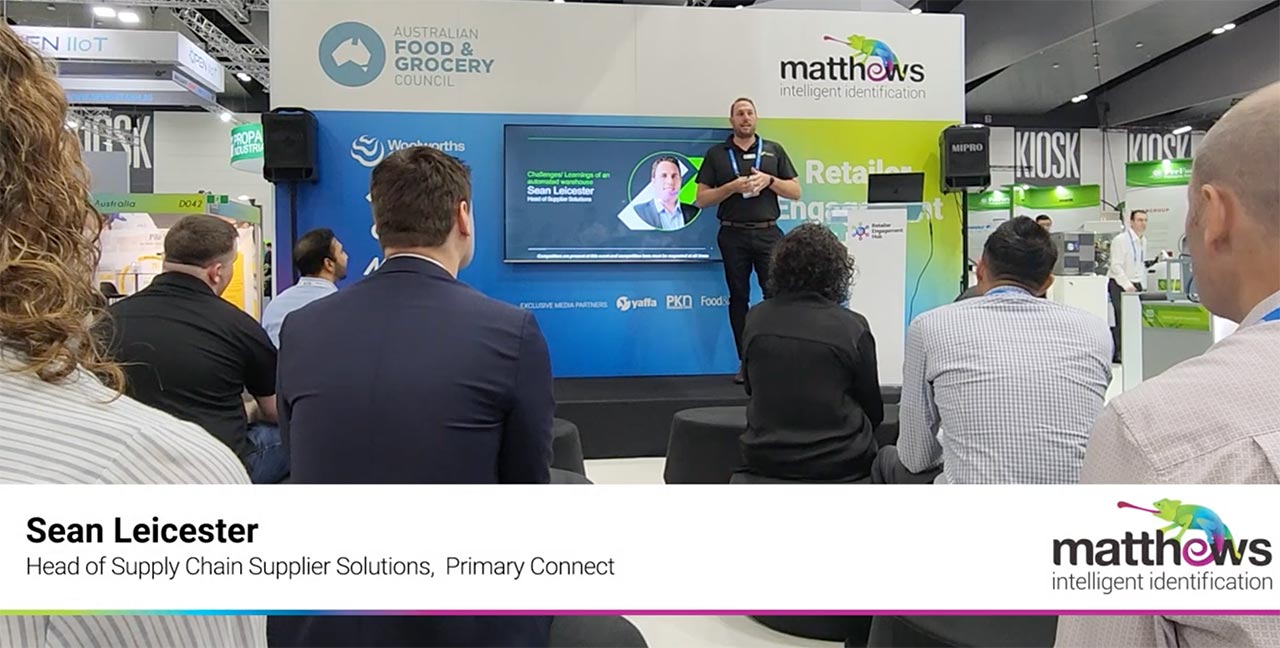

Sean Leicester, Head of Supplier Solutions at Woolworths' Primary Connect, spoke at our Retailer Engagement Hub at APPEX 2024 about the top challenges he sees in automated DCs and how suppliers can avoid costly mistakes.

Wrapping and product overhang are the number-one cause of delays during receiving in automated DC, causing over 50% of stoppages. A staggering 54% of pallets received have contour issues.

Find out the retailer's supplier standards - Coles, Woolworths and Metcash have strict pallet configuration, stacking, and wrapping rules. The Australian Food and Grocery Council (AFGC) also has a series of common delivery guidelines on its website.

Carton integrity is critical to ensure your products make it safely to the supermarket shelves. Crushed cartons cause errors while the delivery is being processed, which leads to stock loss and out-of-stock issues at stores.

Carton integrity is a particularly troublesome issue with shelf-ready packs, where cartons are not strong enough to withstand the weight above and collapse.

SSCC pallet labels are a great enabler for automated DCs, providing:

The issues with pallet labels in DCs used to be as high as 80%, but industry engagement over recent years has reduced non-compliance.

While this is good news, there are still persistent issues with label formatting, poor print quality, incorrect positioning and multiple labels being placed on the pallet. The biggest problem is poor print quality, which means the label needs to be reprinted before it goes to stores.

iDSnet Cloud is a free online labelling tool for carton, crate and SSCC labels. It ensures you print the correct label every time.

You can also get our SSCC Starter Kit, which includes access to iDSnet Cloud, helping you print compliant labels straight from the cloud in minutes.

For more on SSCC labels, check out our quick guide to pallet labelling.

Loose carton flaps cause a massive four hours of downtime per week in Woolworths automated DCs. Packaging issues with glue, tape and sealing can cause serious problems within the network. When carton flaps are loose, the inner product can fall out. The cartons can also trigger automation sensors, which stop machines and result in delayed deliveries to stores.

Automated DCs rely on suppliers to conform to strict standards so products can be efficiently moved to retailers. Conforming with retailer standards prevents rework, saves on costs involved with reworks, and helps avoid product rejection.

Matthews Australasia can help you avoid a costly mistake by ensuring you have compliant SSCC labels. Using iDSnet Cloud, you can get your pallet labels right every time.

Our simple online tool saves you time and makes managing a range of labels to meet complex supermarket standards an easy, stress-free process. You can start using the tool in minutes and print a range of GS1-compliant carton labels, crate GTIN, and SSCC labels from just one central location.

Better still, our SSCC Starter Kit bundles iDSnet Cloud with a robust desktop label printer, so you have everything you need to print compliant SSCC labels in minutes.