Oct 18, 2024 by Mark Dingley

Are you getting your pallet labelling right every time? If not, it could be time to automate.

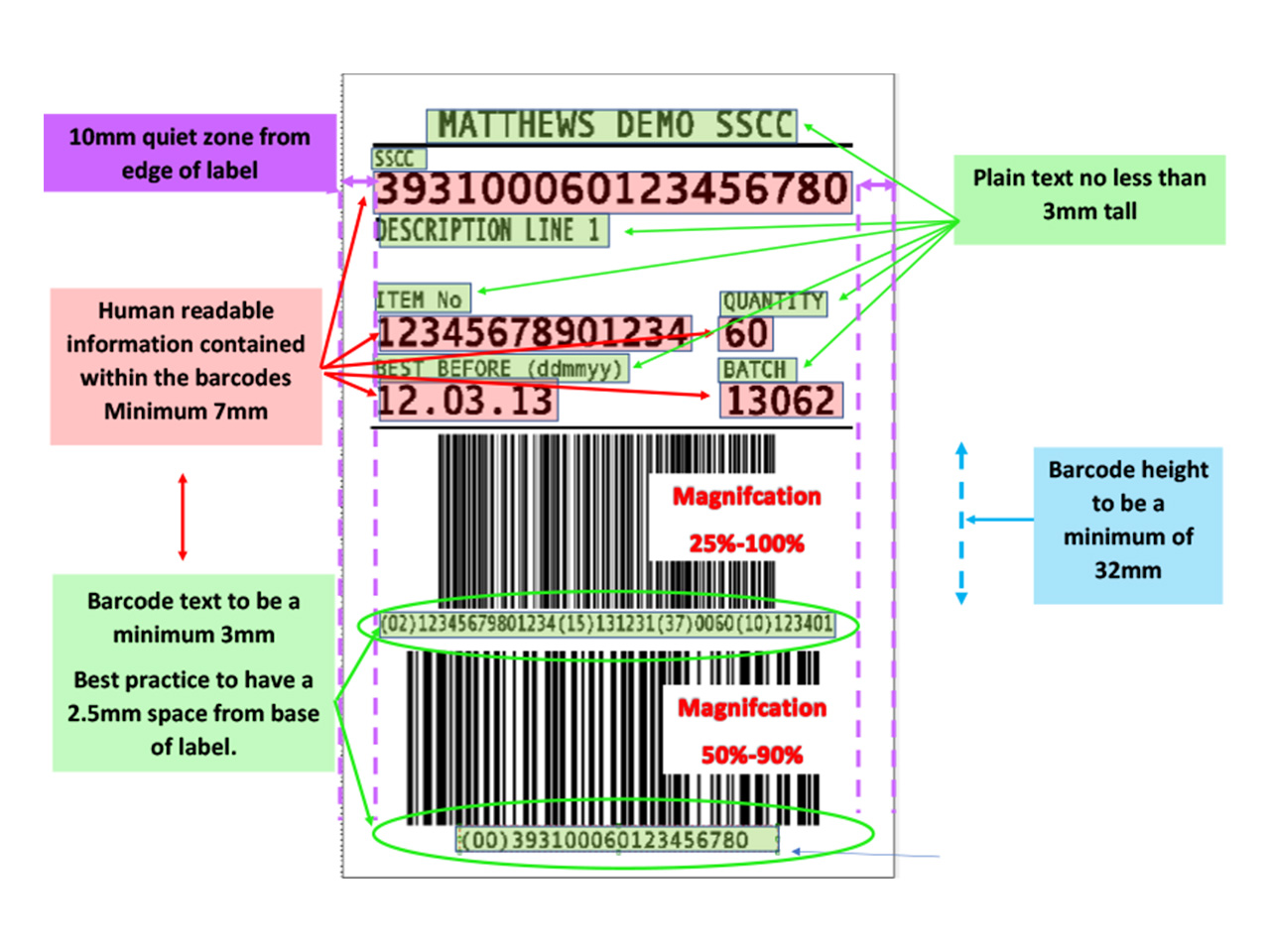

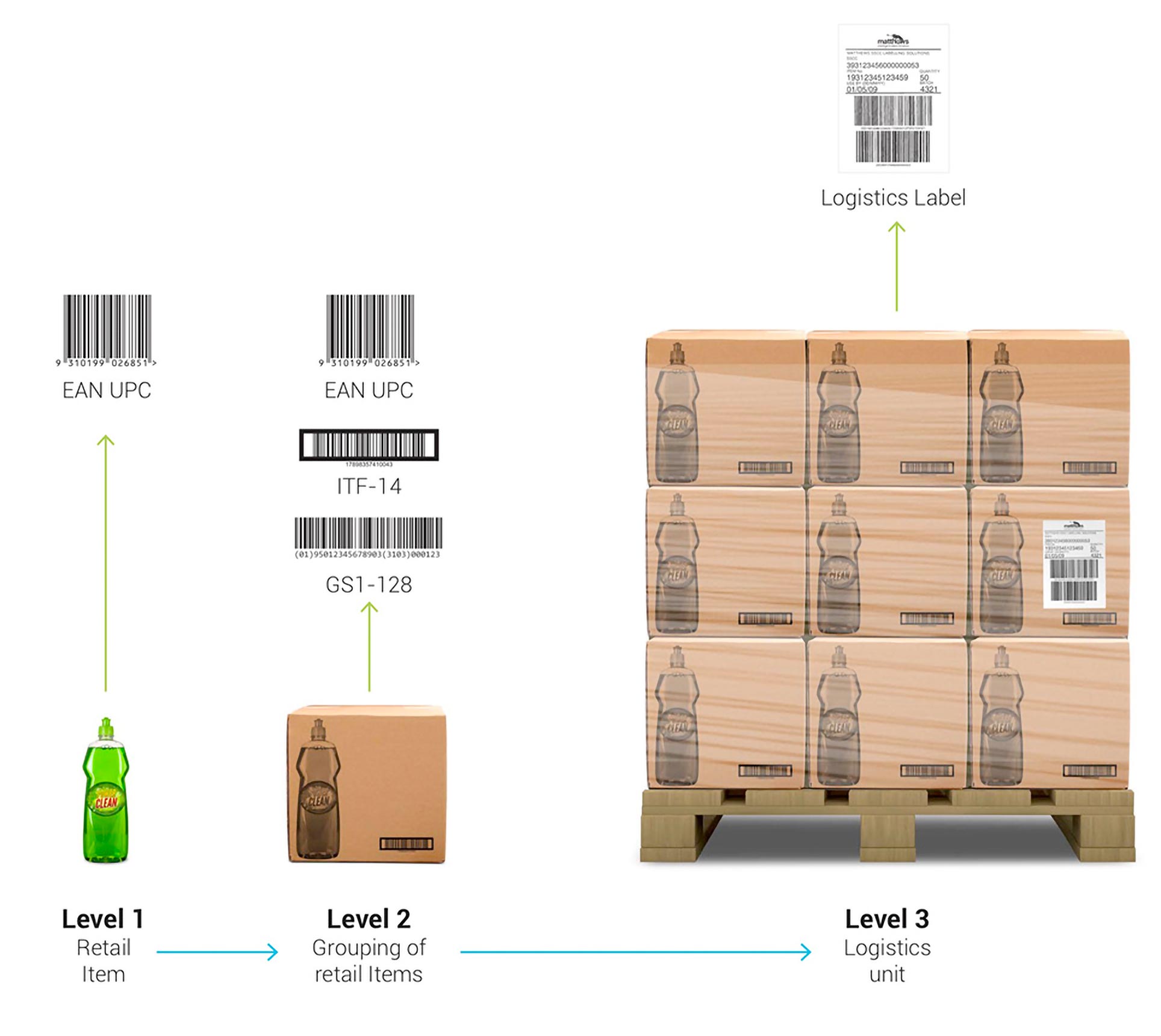

Pallet labels, known as “SSCC labels” (which stands for Serial Shipping Container Code labels”) are a great enabler for distribution centres. The new generation of automated DCs simply cannot operate without them. But when manufacturers get them wrong, not only is it a headache for everyone involved, it can also be a very expensive mistake to fix.

Implementing each retailer’s pallet label requirements to the letter is non-negotiable. Equally important is the ability to print and apply labels to pallets quickly and accurately – with as little human intervention as possible.

Whether you’re relying on manual labelling or out-dated equipment, there’s a solution that can deliver the high-quality pallet labels you and your customers need:

Automated pallet labelling.

In this article, we’ll explain what automated pallet labelling is, what the benefits are, and why you should make the switch. (You may also like to check out “Pallet labelling made easy – your quick guide”. )

Automatic pallet labelling using a pallet label printer applicator (LPA) can provide exact label placement on every pallet. The machine prints information on the labels and applies those labels directly onto pallets. It is often integrated with software, enabling operators to create and change labels easily.

Consider the following scenarios:

1. You’re currently hand-labelling pallets but want to increase production output. Your line is slowing down because employees cannot keep pace.

2. Your pallet-labelling process is unreliable and error-prone. Perhaps you’ve even had products rejected by DCs or had to bear the cost of reworking poor pallet labels.

3. You are supplying products to an automated DC, so you must conform to strict pallet labelling standards. (Here are some more costly mistakes to avoid when supplying to an automated DC.)

Do any of these sound familiar?

If so, automate your pallet labelling before it’s too late.

If you're relying on manual pallet labelling, automation brings many advantages. Manual pallet labelling can become a bottleneck for your production line. The faster a production line, the more difficult it is for operators to keep pace with labelling. So, you either need to slow down your line or sacrifice the quality and accuracy of your labels. Both options will prevent you from maximising output and ultimately cost your bottom line.

Automated pallet labelling increases production capability by providing a faster, more consistent process. Your pallet labels are always precise and accurate, and your labelling can keep up with production speeds.

.jpg)

Here are some of the top benefits:

To illustrate how automated pallet labelling works, consider a simple palletising setup.

On a standard line, cartons are stacked on pallets, wrapped with film, and labelled for shipping.

To automate your pallet labelling, you need to install the LPA at or immediately after the stretch-wrap station. It’s common practice to interlock the LPA with the stretch wrapper, which helps apply SSCC labels on each fork entry on a pallet.

A scanner automatically reads each carton barcode and tells the LPA which label to print and apply to each side.

For example, the Evolabel pallet label printer applicator can apply a label to multiple sides of a pallet at once and scan the labels without the pallet needing to stop. Because operator intervention is minimal, this reduces the likelihood of the wrong label being applied to a pallet.

Evolabel can be integrated into a turntable, allowing pallets to be labelled on two sides by one machine. It also allows you to label dual stack and variable height pallets (e.g. butt pallets) without human intervention, thanks to the motorised stand.

For the best results, integrate your LPA and scanner with package code management software to automate the end-to-end printing, application, and verification process for carton and pallet labels. Matthews iDSnet software allows you to integrate label validation to ensure the accurate label is applied to the right pallet at the right time and barcodes are readable and scannable. You can also keep track of labels more accurately and be confident products will be accepted at the DC.

Watch how SunRice transformed its pallet labelling with new label printer applicators. Matthews installed LPAs onto their palletising systems to print and apply industry-approved SSCC labels. iDSnet software acts as a centralised point of control for production facilities, which helps reduce the risk of coding and labelling errors.

Label pallets efficiently, safely and with ease with the Evolabel A-Series Pallet Label Printer Applicator.

Need some help upgrading to automated pallet labelling? Get in touch with Matthews. Our experts can help customise a pallet-labelling solution that fits your production line and customer needs.

Need to brush up on your pallet labelling know-how? Master pallet labelling in our Barcode Academy.

You may also like to check out “Pallet labelling made easy – your quick guide”.