Dec 12, 2024 by Mark Dingley

The countdown is on: by 2027, retailers will be scanning 2D barcodes at checkout – and suppliers must keep up.

Woolworths is already transitioning to this new standard, and it’s expected that others, including Coles, will quickly follow suit.

Suppliers who act now and transition to the 2D barcode can reap the benefits, including freeing up valuable label space by using the much smaller 2D barcode (see below for a size comparison).

Matthews Australasia has collaborated closely with major Australian retailers as they prepare to deploy 2D barcodes. This collaboration has provided us with valuable insights and guidelines, which we are sharing here to help you ensure your products meet retailers’ 2D barcode requirements.

Two-dimensional (2D) barcodes look like squares or rectangles made up of lots of small dots. They are embedded with data and can hold significant information in a small space. This information is revealed to the retailer, supplier or customer when 2D imaging scanners or vision systems scan the code.

There are two main types of 2D barcodes being planned for:

1. GS1 DataMatrix

2. QR code

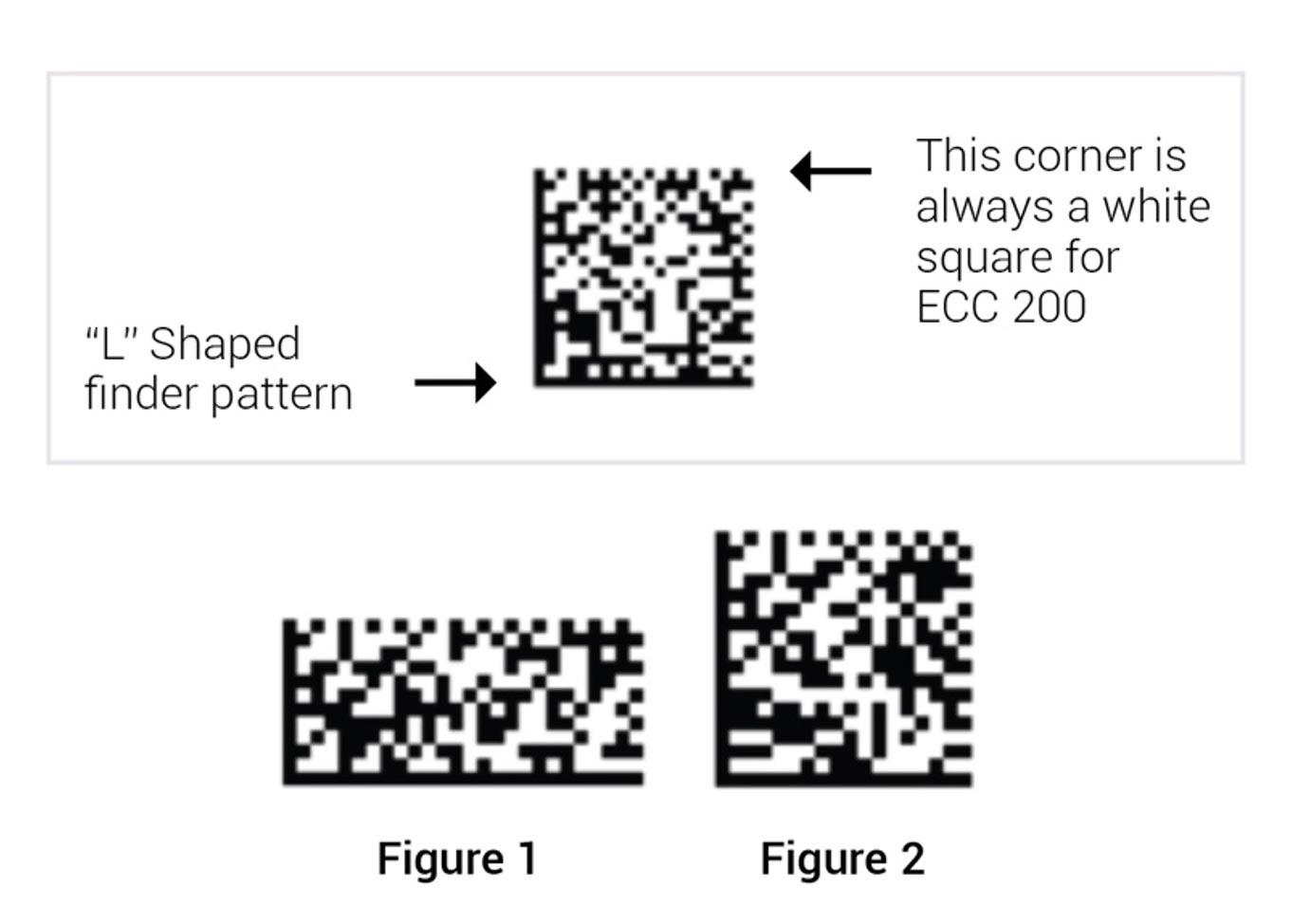

DataMatrixbarcode, source: https://www.matthews.com.au/data-matrix-code

GS1 DataMatrix is the current 2D barcode type used by retailers. It is popular as a transition due to the capability to utilise GS1 application identifiers such as the current EAN 13 or GS1-128.

The DataMatrix barcode symbol is a 2D matrix barcode made up of black and white “cells” or modules that can be arranged in a square or rectangular matrix. These barcodes embed additional valuable information such as use-by and best-before dates, batch/lot ID, weight and price. This means product identification and product information can be contained in the barcode, which is valuable for food safety, traceability and date-code management, which helps reduce food waste.

This article will focus specifically on GS1 DataMatrix barcodes, which are being implemented in many supermarkets. However, it’s worth considering how your technologies and processes can scale to meet the needs of the GS1 Digital Link embedded QR codes, which will be the next stage of the 2D journey.

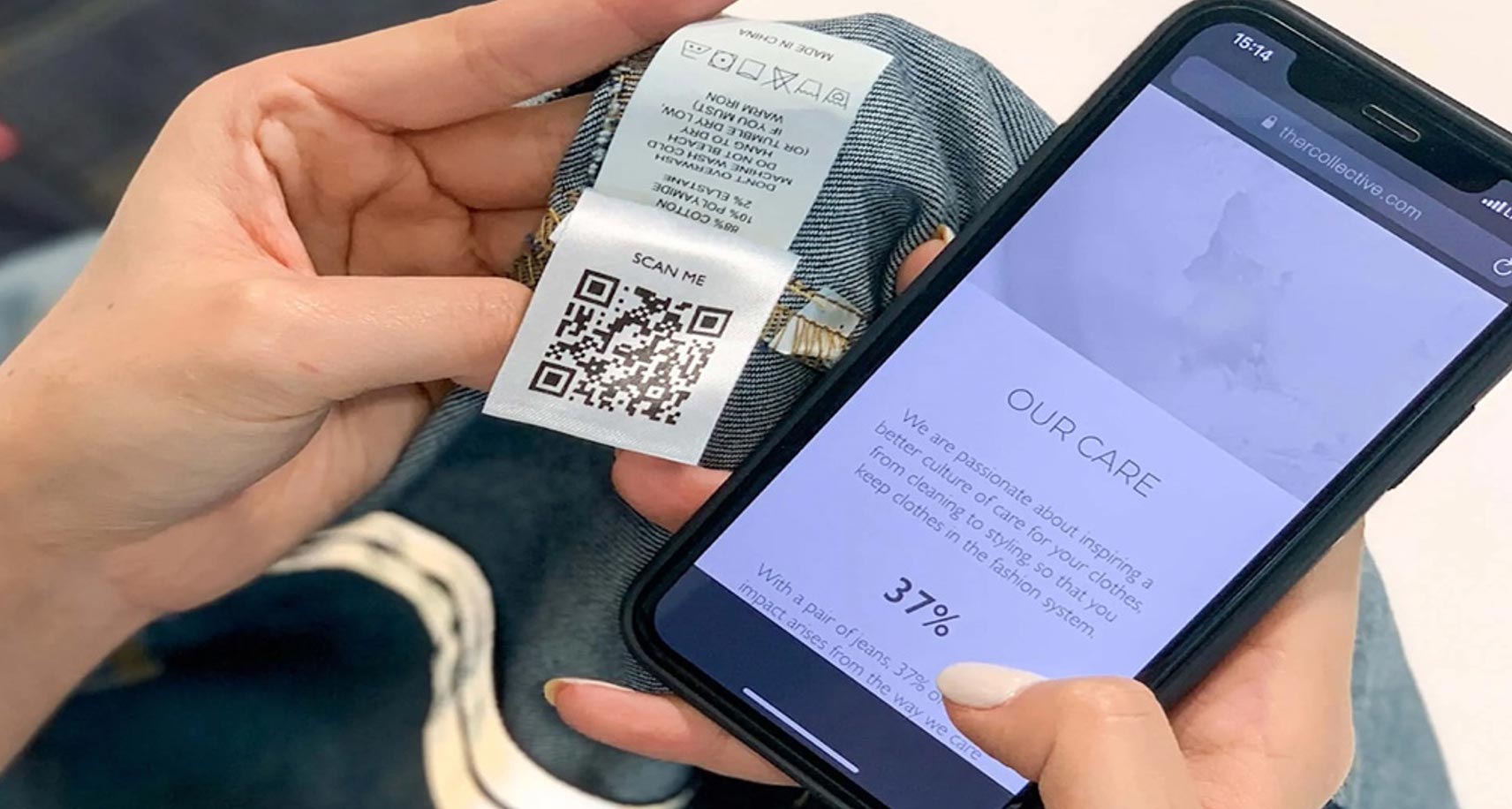

QR code, source: https://www.matthews.com.au/qr-code

Like retailers, suppliers can also benefit from using 2D barcodes.

One of the most significant benefits is in the event of a recall or withdrawal. 2D barcodes allow more targeted and accurate recalls utilising the embedded data, saving food from unnecessarily being sent to a landfill. When a product’s batch, lot or serial number is encoded into a 2D barcode, it allows you to identify affected products anywhere across the supply chain, so only the affected products need to be withdrawn from store shelves. All other products can remain on the shelf for sale.

Another benefit of 2D barcodes for suppliers is their size: if you put them side by side, a 2D code is less than half the size of the widely used linear EAN-13 one-dimensional barcode. This saves space on packaging while encoding more information.

The biggest question you’ll want to answer is: should I upgrade my equipment to print 2D barcodes?

First, look at your existing coding setup and answer the following questions. If you need help answering these questions, talk to your operations and IT team or your coding equipment provider, such as Matthews Australasia.

Enhancing the consumer experience: consumers can use their smartphone to scan the QR code on packaging containing a GS1 Digital Link Uniform Resource Identifier (URI). This points them to a brand web page filled with recipes, nutritional information and more content. The consumer can also use a retailer app to scan the same barcode and be connected to different experiences, such ordering products, collecting loyalty points, price matching, and sharing on social media

When considering whether your technology can print 2D barcodes, it’s important to understand exactly what you need to print.

For manufacturers to shift to 2D codes seamlessly, you need to be able to print inline.

For this, you need equipment capable of printing barcodes directly onto packaging during production. For instance, Thermal Transfer Overprinting (TTO) technology is designed to code onto flexible film packaging, labels, generic flow-wrap packaging and other substrates used in fresh produce and meat goods. If you're already using this to print onto bags, such as salad bags, all you need to do is add a 2D barcode and you’re good to go.

The next step is to test your 2D coding capabilities with the following embedded data elements using their application identifiers (in brackets below):

An example of a random weight article would be a steak priced by the kilo. In this case, the code would contain:

Once printed, send test samples to your retailer for feedback.

Without accurate and scannable barcodes, retailers can’t stock your products, and customers can't buy them.

That’s why all major supermarkets will ask you to provide a Barcode Verification Report before they stock your products. This applies to your 2D barcoded products, too.

A Barcode Verification Report can be obtained through GS1 Australia’s Barcode Testing Service. It measures whether your barcodes meet ISO/IEC benchmarks for quality in terms of readability and scanning. It also assesses other elements, including size, colour, quiet zones (light margins) and barcode location. The report will provide details of your barcode compliance and any changes you need to make.

To get a Barcode Verification Report, simply fill out the form and send your products to GS1 Australia offices in Melbourne or Sydney.

The move to 2D barcodes is happening now, and being proactive can secure your place on supermarket shelves. Start assessing your printing systems, connect with retailers for their specific requirements, and work with trusted partners such as Matthews Australasia to ensure a seamless transition.

As a GS1 Strategic Alliance Partner and 2D barcode expert, Matthews has the knowledge and expertise to help you select the appropriate 2D barcode solution for your business and meet evolving retailer needs. Talk to us about your unique needs.

Go to our 2D Barcode Learning Centre. It contains videos, articles and resources to help you understand how to create the codes, what technologies to use, and how to ensure your 2D codes meet retailer specifications and scan properly.

To test your team’s knowledge and achieve compliance with 2D barcodes, go to our Barcode Academy.