Jun 13, 2024 by Mark Dingley

From BMW to Amazon, global companies are beginning to employ humanoid robots. So what does this mean for manufacturing? And is Australia next?

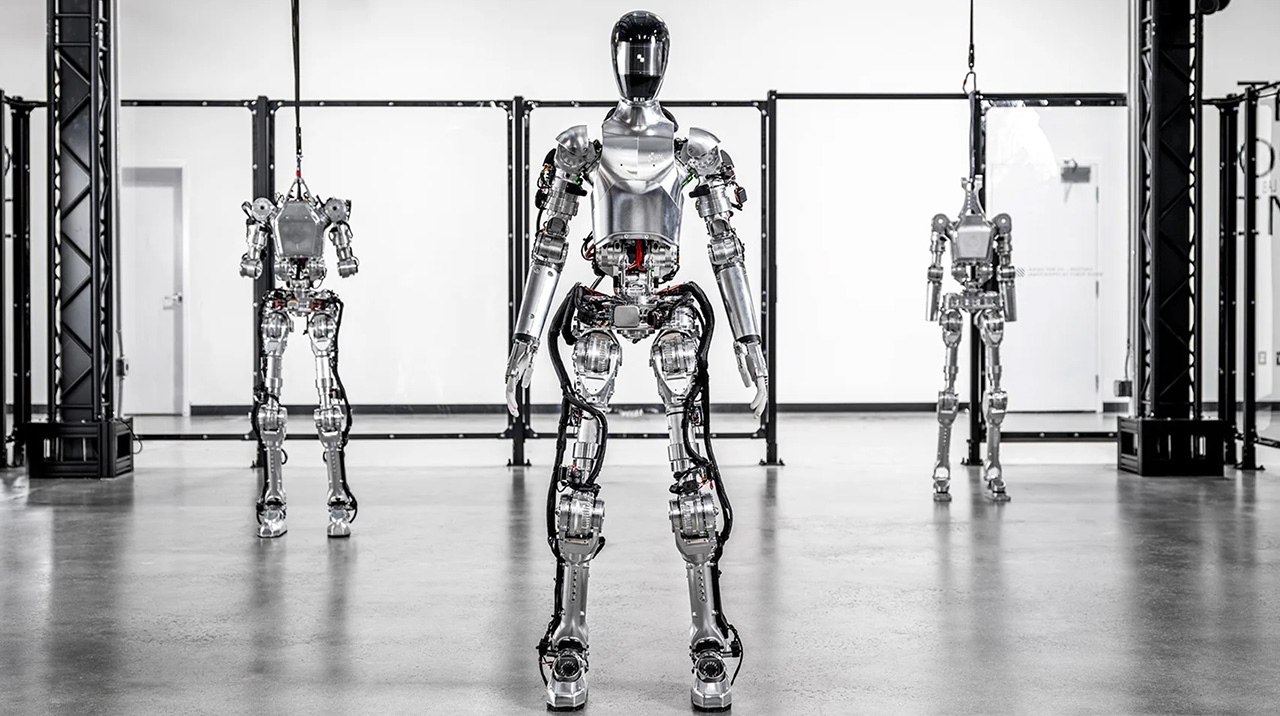

BMW’s newest autoworker in its South Carolina (USA) plant is 170cm tall, walks on two legs, uses five-fingered hands to assemble machines and takes a break every five hours to walk to a charging station and plug itself in.

Still in America, over in Seattle, Amazon’s newest bipedal employee can sense, grasp and move bulk objects with two robotic arms, and has LED eyes that blink to indicate which way it’s turning.

Once the stuff of science-fiction movies, humanoid robots have come a long way in the past few years, and now, a handful of companies are deploying their robots for commercial pilot projects.

BMW is the first commercial contract for the Californian robotics and AI company, Figure. The car manufacturer has already integrated an array of robotics into its South Carolina plant, and asked Figure to help it solve further automation issues with more dextrous and mobile manipulation.

It’s not yet clear what the robots will be doing for BMW. In a statement, Robert Engelhorn, president and CEO of BMW Manufacturing, said robots have “the potential to make productivity more efficient” and “enable our team to focus on the transformation ahead of us”.

And Figure is just one of many companies racing to bring humanoids into the workforce.

Agility Robotics makes a humanoid robot called Digit specifically for warehouses. Amazon invested in Agility as part of the Amazon Industrial Innovation Fund, so it’s no surprise that Amazon is testing Digit in its own warehouses.

Digit can move, grasp and handle items, traverse stairs, crouch into tight spaces and move items on and off pallets and conveyors. Amazon says Digit can also work collaboratively with employees.

Seeing the growth potential, Agility is set to open a robot-making factory in the US state of Oregon, which will produce up to 10,000 units a year.

Agility’s Digit robot. Source: GXO Logistics, Inc./TNS/TNS

Agility’s Digit robot. Source: GXO Logistics, Inc./TNS/TNSNamed by ‘Time’ magazine as one of the top inventions of 2023, Phoenix is created by Canadian tech firm Sanctuary AI and powered by Carbon, a software platform that uses sophisticated AI to let the machine think and act like a real human worker. This combination of AI and “industry leading robotic hands” could be a game-changer.

You only need to watch the video of Phoenix to understand what these robots are truly capable of. Sanctuary AI says its robotic hands can rival human hand dexterity and fine manipulation, due to its proprietary haptic (relating to the sense of touch) technology that mimics the sense of touch.

Geordie Rose, Sanctuary AI’s co-founder and CEO, said at the launch:“We designed Phoenix to be the most sensor-rich and physically capable humanoid ever built and to enable Carbon’s rapidly growing intelligence to perform the broadest set of work tasks possible. We see a future where general-purpose robots are as ubiquitous as cars, helping people to do work that needs doing, in cases where there simply aren't enough people to do that work.”

Source: Sanctuary AI

Source: Sanctuary AITexas-based Apptronik launched its humanoid robot, Apollo, in 2023 and the US company has partnered with Mercedes to test how Apollo can help in its Hungarian production assembly line. The company is also working with NASA on humanoid-robot commercialisation, and hopes to use them in space exploration.

Source: Apptronik

Source: ApptronikYou knew Tesla would feature somewhere on this list, but surprisingly, Elon Musk’s humanoid isn’t as far advanced as you might expect. Tesla aims to create a general-purpose, bipedal, autonomous humanoid robot capable of performing unsafe, repetitive or tedious tasks. After an underwhelming launch of Optimus, Tesla has upped its game with previews of Optimus Gen 2.

Most impressively, the revamped humanoid can manipulate delicate objects, such as eggs, without crushing or dropping them. It’s early days, but this dexterity in the fingers and fingertips shows that the robot could easily be applied to factories.

Source: Tesla

Source: TeslaRobots have long been essential tools on auto assembly lines, but this is the first time that autonomous humanoid robots will join the workforce – and they could have significant labour-market implications.

Humanoids are already showing their capacity to be adopted for use in manufacturing supply chains, taking over tasks deemed too dirty, dangerous or dull for human workers.

Jeff Cardenas, co-founder and CEO of Apptronik, told Business Insider robots can free human workers from dangerous tasks and allow people to spend their time better.

“The robots will do the things that we don’t want to do, that injure us, that drive people out of these industries, and it’ll allow people to gain new skills and do work in new ways,” he said. “It'll start in the supply chain and start in these activities where we have the technology today. The sky’s the limit for where it goes from there.”

But first, they need to provide a tangible ROI.

When Amazon wanted to test Digit in its warehouses, they needed to find a case where the technology can provide real value while being scalable and profitable.

For Amazon, that value is in the simple task of moving e-commerce totes – standardised containers that warehouses use to store and transport items. As items enter or leave the warehouse, empty totes must be continuously moved from place to place. Even in highly automated warehouses, the job is done mainly by humans, meaning robots can add real value.

Automakers have also been looking to lean on robots to combat rising labour costs, the Wall Street Journal reports. Mercedes-Benz began trialling Apollo robots at a factory in Hungary, where automakers have been experiencing labour shortages for several years as workers migrate to Western Europe.

In Mercedes-Benz's factory, the Apollo humanoids have been assigned roles that streamline logistics within the factory setting, such as transporting components to the assembly line and organising kits needed for vehicle assembly. One of the top benefits of humanoid robots is that manufacturers can automate tasks without redesigning their existing facilities, as humanoids can work in the same space as humans. They also feature in-built safety mechanics, allowing them to operate close to their human colleagues without posing risks.

With the clear benefits of humanoid robots, we can expect to see their gradual integration into Australian manufacturing processes, along with other advanced robotics and automation. However, the cost and availability of these robots means it will be a while before they are adopted in any great numbers.

Source: Apptronik

Source: ApptronikThe image of fast-moving industrial robots with heavy arms swinging dangerously within a cage is quickly becoming a thing of the past. The new generation of robots is smarter, nimbler, more mobile, more collaborative and more adaptable. They can take on more jobs, work more autonomously from humans, and do so with more precision.

But it’s a big leap between commercial trials and widespread adoption. As Amazon Robotics vice president Scott Dresser told The Australian: “We want to see how it plays out. It is an experiment at the end of the day. Do employees know how to interact with it? Do we know how to build processes around it? Is it fast enough?”

It’s not enough to simply build a robot that can do a few tasks. The robot has to perform with the kind of safety, reliability and efficiency that will make it a viable alternative to humans. But with companies racing to develop humanoids, it’s definitely a space we should watch.