Oct 14, 2020 by Mark Dingley

Manufacturers that develop a reputation for exceptional quality gain their customer's esteem and confidence and are set apart and above the competition.

Conversely, if they instead developed the distinction of producing unreliable or low-quality products, especially with the proliferation of online review and comparison sites, the damage to their brand and business, can quickly become ruinous.

Quality matters, but how do you know which measures to manage, or what data to monitor to maintain, let alone improve product quality?

The answer lies in capturing and acting on the right quality metrics.

Regardless of industry or size, manufacturers must have a holistic overview of their business to identify areas for improving processes and enhancing efficiency.

Quality metrics are also critical to ensuring your manufacturing plant, processes and products are meeting internal and external quality, regulatory and compliance standards.

Below we are going to explore the main metrics that combined form the framework for a sound quality control system for manufacturers.

How many products turn out right the first time around, that is to say, that they progress through your production line and are delivered to the end customer without fault or requiring rework?

Three essential measures that can help determine whether a production process has an inherent problem, and is resulting in waste are:

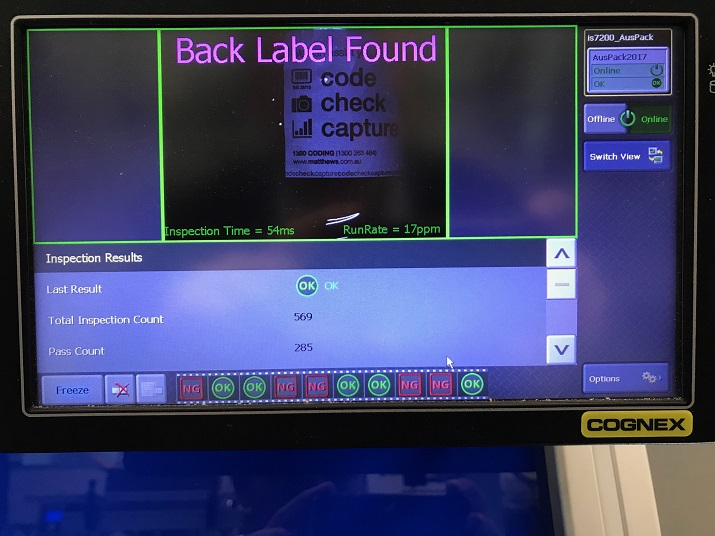

Incorporating Matthews iDSnet software into your production line not only enables you to integrate all of your coding, labelling and other end-of-line packaging equipment but also provides a fast and reliable way to capture and report these quality metrics.

iDSnet allows you to track and monitor the number of rejects, assigning a reject code to the reason for rejection and the volume outcast in a set period.

By setting a 'normal' tolerance threshold, the operator is immediately alerted when rejects exceed this level so production line issues can be fixed before there is any further waste.

What percentage of materials sent into your production line never make it to becoming a finished delivered product?

This percentage is the scrap rate, knowing this metric is critical to business profitability because it measures the amount of wastage involved as an operational cost.

Beyond base scrap rate, if your company employs a lean manufacturing philosophy, a valuable benchmark of business performance and capability can be to measure defects per million opportunities (DPMO), or parts per million (PPM).

Supplier Defect Rate is a crucial measure for production lines that operate with a multi-tiered and complex supplier base.

Determine supplier defect rate by measuring the percentage of materials and products received throughout the entire supply chain that don't meet your quality and compliance specifications.

This rate can be tracked using DPMO or PPM mentioned above. For example, if a shipment of 1,000 pieces had 22 defective pieces:

22 / 1000 = 0.022 or 2.2% rate of defect, which can then be extrapolated to 0.022 x 1,000,000 = 22,000 parts per million (PPM).

Depending on the complexity of your supply chain, Supplier Defect Rate can become the benchmark by which to measure not only your suppliers but also your supplier's supplier quality.

This metric is important because with every defective part that makes its way to your production line increases your risk of disruption and could compromise your product quality.

Understanding the entire cost and impact inferior quality supplier parts has on your bottom line extends beyond the replacement costs of defective parts. If that defective part has led to disrupted production across multiple and dependent lines, your output may come to a standstill.

While Supplier chargebacks measure refunds or charges for materials and parts that fail to meet your quality and compliance specifications, it doesn't capture the downtime costs relating to managing those faulty supplies.

By measuring non-material defect costs, such as tracking production delays, cost of carrying inventory, costs resulting from late delivery, etc. you then have a clear record of material and parts expenses and the impact costs of defective supplier parts.

As the final arbiters of the quality of your products and service, it is essential that customer feedback factors into your quality metrics.

By developing a system and customer-focused culture of continuously collecting, analysing, and most importantly acting on customer feedback, this critical information can improve your business.

Two areas of focus should be:

Building customer feedback capability and culture takes time but is an investment in the continuous improvement in the quality of your products and service.

If you are ready to take your manufacturing business to the next level and lock in a reputation for exceptional quality using the above metrics will help you understand what is happening along your production line. Once the causes and costs of defects are available for analysis, you can start to focus on the steps or changes needed to reduce those defects and costs.

As experts in information-driven manufacturing, the team at Matthews Australasia have the tools and knowhow to help you capture the right data across your production line to ensure your business is consistently the best it can be.