Jul 15, 2020 by Mark Dingley

Adapt to survive. That’s the mantra for businesses in the middle of the COVID-19 crisis.

For food and beverage manufacturers, this means looking for new ways to drive efficiency and profitability.

One proven strategy for large and small manufacturers is using generic packaging as an alternative to pre-printed packaging,

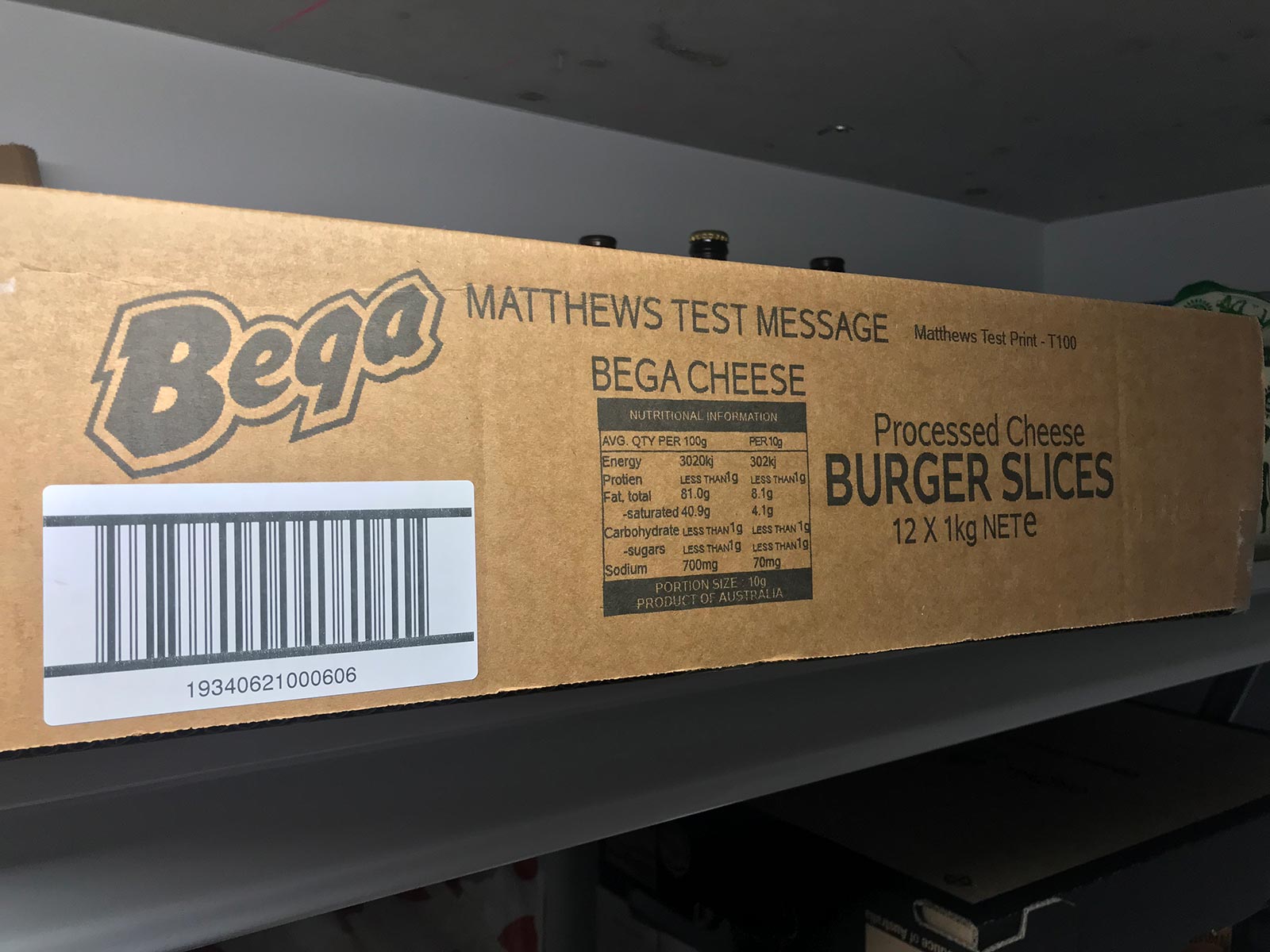

Generic packaging is plain packaging, such as film or cartons, that you can print your own nutritional information, date codes and messages to suit the specific product.

So, rather than using pre-printed cartons or shippers for packing and shipping product, you use plain packaging and print the product details on demand using direct coding or print-and-apply labelling with an LPA.

Types of generic packaging include:

Because it lets you be agile.

We’re in an uncertain time with lots of unknowns, which means you need to be as flexible as possible in your approach to products, packaging and marketing. Generic packaging lets you do that.

Because you’re not investing in stocks of pre-printed packaging, you can be more market reactive. Focus on making the products that are selling best right now and print packaging on demand.

Let’s say you make frozen pizzas. Rather than focusing on ten different gourmet pizza flavours, in order to be profitable and efficient, you need to maximise production volumes on fewer SKUs.

So, you pivot your production lines.

If you use generic secondary packaging, there’s no need to worry about wasted stock of pre-printed packaging for your now-obsolete pizza varieties. You simply order the generic packaging and use in-line printing when you need it.

The same applies if you had pre-printed packaging from discontinued lines or seasonal promotions. Less waste means more savings.

You also won’t need to change your packaging every time you do a product changeover, which means greater efficiencies. And time is money.

The first thing most manufacturers ask us when considering generic packaging is “what’s the cost of the box and printing?”

But the reality is the benefits of generic packaging cannot be measured in dollars saved on boxes alone. You need to put a figure on savings across the business.

One substantial cost saving is in inventory costs.

Inventory costs can add up for manufacturers, and in this environment, every saving counts. With generic packaging you aren’t tying up much-needed capital in pre-printed packaging inventory.

With less frequency of ordering, you also save on the indirect costs of transport, administration and handling. You may not need a full warehouse for packaging, because there’s less space needed for individual SKU packaging.

Generic packaging can also improve your end-product quality.

The problem with individual SKU packaging is that you have to order in bulk, which means it can end up sitting around for months before being used. The longer it’s in storage, the more moisture it absorbs, which means it doesn’t run reliably through the case packer.

Generic packaging spends less time in storage because it can be used for most SKUs. As a result, it retains its structure and quality.

Generic packaging simply requires less planning than pre-printed packaging, which means you don’t have to worry about long lead times before getting your packaging. Not to mention the disruptions from COVID-19 if you usually order your pre-printed packaging from China.

Instead, you create and change messages in your printing software as you need it. This means you can bring new products and promotions to market much faster.

Without the need to change packaging for different product SKUs, you benefit from faster changeovers.

This is the case for smaller manufacturers who change products or packaging multiple times a day, as well as contract manufacturers and co-packers working for different brands.

With generic packaging, changeovers are as simple as programming or selecting a new message in the coder. You can have a line ready for coding new packaging in a matter of minutes.

Generic packaging offers advantages for both. Smaller manufacturers tend to change products or packaging multiple times per day, so generic packaging can offer huge time savings. By using generic cartons, the cases are only changed when a different size is required. Instead, messages are quickly and easily programmed into the coder in just minutes.

Large manufacturers, on the other hand, benefit from the savings associated to inventory. Depending on the number of product lines, it could mean saving a whole warehouse of storage.

If you’re not sure if you will benefit from generic packaging, we recommend starting by talking to our specialist team.

The types of manufacturers we’ve helped move to generic packaging include snack foods, dried foods and confectionery, and food service products.

Read how the Gourmet Nut Company uses generic film to create efficiencies and save costs.

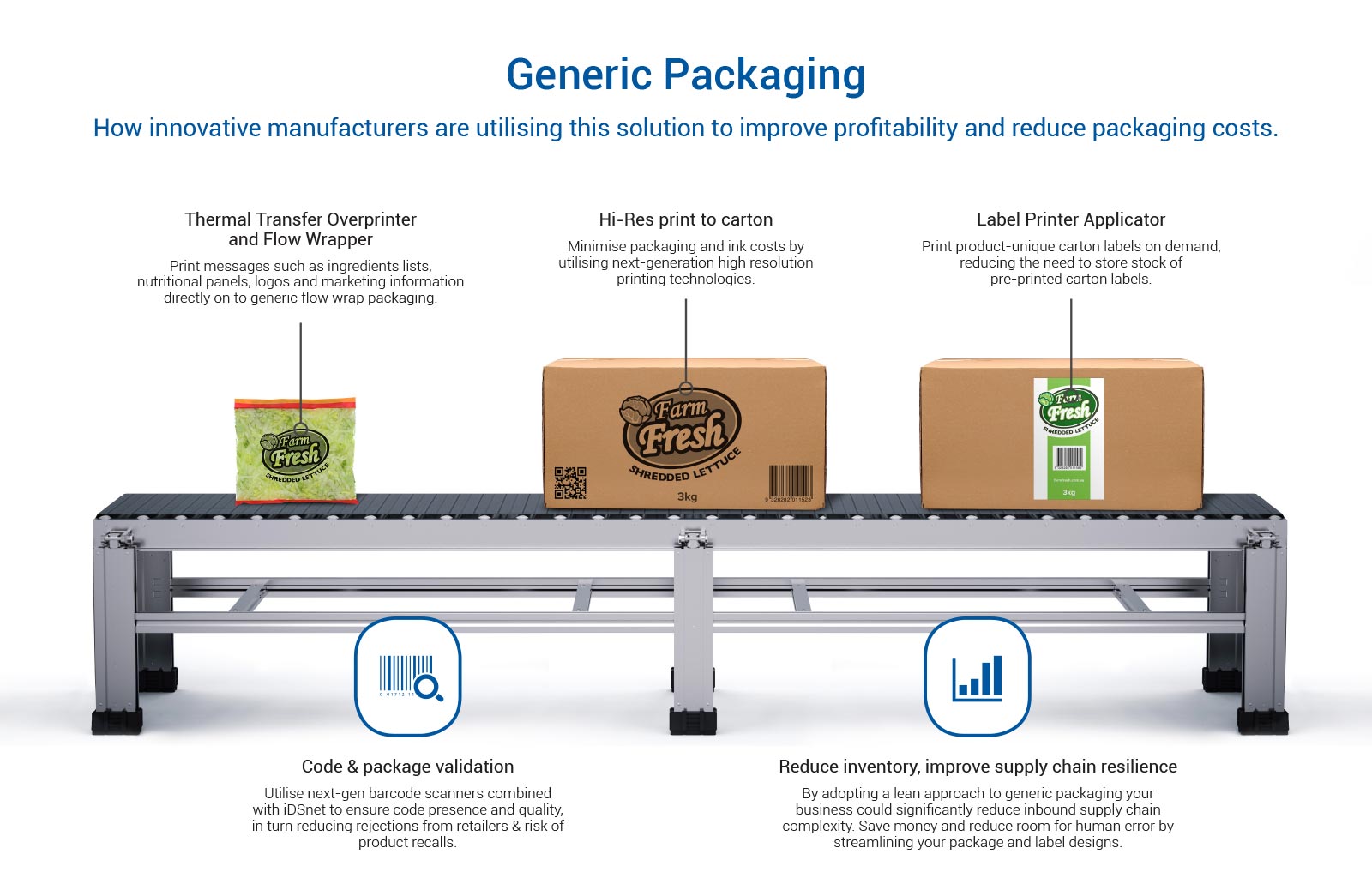

Print messages, such as ingredients lists, nutritional panels, logos and marketing information, directly onto generic flow wrap packaging or flexible packaging. TTOs use a high-resolution thermal printhead to produce crisp, clear barcodes and information.

Print messages and codes onto cartons using next-generation high resolution printing technologies. They are ideal for generic package coding onto cartons and corrugated boxes and suitable for use in a wide variety of environments.

Print and apply product-unique carton labels on demand and apply them onto cartons on the production line.

A software integration package, such as Matthews iDSnet, helps you link it all together for easier message design, quick product changeovers and real-time line status monitoring.

Want to pivot to generic packaging? Find out if it’s right for your business by talking to our experts.