Sep 13, 2024 by Mark Dingley

In 2022, we highlighted nine sustainable Australian companies that manufacturers can learn from. Now, with sustainability more critical than ever, Australian entrepreneurs and leaders are raising the bar on sustainable innovations and actions. Here, we've shortlisted nine more companies to inspire your sustainability agenda.

These Australian companies, regardless of their size, are not just ticking the box. They are conducting research, inventing and collaborating to make a significant, measurable impact in the sustainability space. Their actions are not just inspiring, but also a testament to the potential of sustainability in the business world.

Image credit: https://www.zeroco.com.au/

Zero Co is on a mission to “untrash the planet”. Since 2019, this Australian company has been at the forefront of the battle against plastic waste with its unique refillable home cleaning and body-care products.

How does it work? Customers purchase a set of “forever” bottles made from 50% recycled ocean plastic and refill pouches containing 40% recycled materials. When it’s time to refill, the pouches are returned in prepaid mailers to be cleaned, refilled and reused, ending single-use plastic. Each Zero Co product also contains a tracking code, so customers can see where the plastic has come from.

The Zero Co team is not just talking the talk, they’re walking the walk. They’re actively involved in large-scale ocean clean-ups, with their first clean-up in Indonesia removing the equivalent of 500,000 water bottles worth of plastic from the ocean. Their efforts have since grown, with over 32.5 million water bottles of ocean waste collected.

How do we deal with soft plastics? It’s one of the most challenging sustainability dilemmas for businesses globally. Soft plastics are hard to recycle and significantly contribute to landfill and CO?emissions. The problem has escalated with the collapse of the REDcycle plastic recycling program.

To help solve the dilemma, Amcor Flexibles Asia Pacific has created AmPrima, which won this year’s Manufacturing and Consumer Goods category in 'The Australian Financial Review Sustainability Leaders list.

AmPrima is a new recyclable, heat-resistant film engineered to replace non-recyclable nylon and polyethylene terephthalate (PET). It allows global consumer goods companies to eliminate the hard-to-recycle elements from pouches, shrink wrap, film, bakery bags, wipes packaging, trays and cups. The innovation is expected to reduce 300,000 kilograms of non-recyclable packaging from the consumer goods supply chain in Australia and New Zealand in 2024.

Amcor was also the world’s first packaging company to pledge to make all its products recyclable or reusable by 2025.

Moving to solar could, on average, save customers $1,000 a year on their energy bill. But the journey to get there can be complex.

That's where Brighte comes in. Brighte is a renewables lender that works with state governments and large companies through its enterprise program to promote the move to clean energy.

The Brighte Sustainability Program gives customers information on where to start, guidance on who to use (courtesy of its network of over 2,500 accredited tradies) and payment solutions – which are particularly helpful during the cost-of-living crisis. Following its success with households, the company is also seeing growing demand from large corporations looking to increase electrification and efficiency at scale.

This initiative helped the company win the Banking, Superannuation, and Financial Services category at the 2024 AFR Sustainability Leaders Awards.

Image credit: https://brighte.com.au/media/

Consumers are demanding more sustainable packaging, and Accolade Wines has delivered. Wise Wolf Wines by Banrock Station uses 91% recycled glass bottles developed in partnership with Visy Glass.

But they haven’t stopped there: The labels are made from 100% upcycled sugarcane, cardboard shippers are made from 100% recycled paper pulp, and bottle caps are made with 26% less materials than a standard cap – 40% of which is recycled aluminium. There’s also a QR code on each label, which provides consumers with details of the environmental attributes of each packaging component.

Banrock Station is known for its bold sustainability actions. In 2022, it launched 100% recycled plastic eco bottles in Australia and the UK, and has contributed more than $7.5million in funding for conservation projects across 13 countries, from maintaining wetlands in the South Australian Riverland to protecting turtles in the Great Barrier Reef.

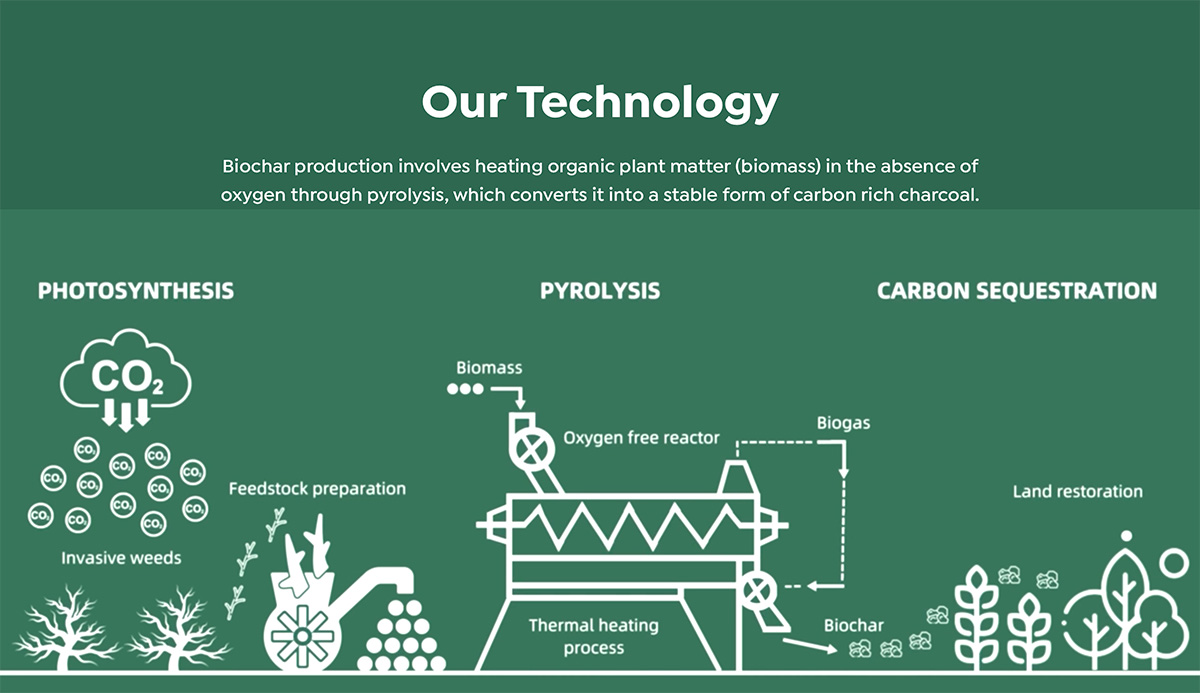

What if you could turn a destructive weed into a replacement for coal? It might sound far-fetched, but it's the reality for Biomass Projects.

The company plans to build the world’s largest biochar production on a 225,000-hectare plot in the Western Australian Pilbara region, which is overrun with mesquite.

The government recognises mesquite as a Weed of National Significance. As such, it poses a severe threat to the local ecosystem, making it the ideal plant to experiment with. In the biochar production process, the organic plant matter (mesquite) is heated in the absence of oxygen through pyrolysis, which converts it into a stable form of carbon-rich charcoal.

The plant will pyrolyse 10.5 million tonnes of biomass over 20 years, meaning 10.2 million tonnes of carbon dioxide (CO?) will be removed – equivalent to greenhouse gas emissions from 2.2 million cars. When applied back to the land, the biochar also restores the ecosystem to its original state by increasing water retention and soil fertility.

Image credit: https://biomassprojects.com.au

Cement is the most widely used substance on Earth after potable water. But the cement industry is responsible for at least 8% of planet-warming CO?emissions – more than those from aviation. If the cement industry were a country, it would be the fourth-largest national emitter in the world, behind China, the USA and India.

Nu-Rock Building Products Australia is setting out to change that. The company makes building products from waste materials such as coal ash and steel slag. According to founder Maroun Rahme, by implementing this technology “and doing nothing else”, Australia could achieve its net-zero target by 2030.

A chemical-curing process turns waste products into formulated rock that can be shaped into building blocks. During curing, the blocks absorb CO? to create the world’s lowest embedded energy concrete or cement substitute product, as verified by the CSIRO, University of NSW, and Western Sydney University.

And the cherry on top? There is almost an endless supply of waste material used to make bricks, blocks, pavers, and other products using Nu-Rock’s method.

A staggering 42% of Australia’s annual food waste comes directly from the commercial sector. As much as 3.2 million tonnes of food goes to waste before it reaches supermarket shelves.

Tackling this issue is Yume, a food redistribution startup.

Yume has devised a food redistribution platform that helps prevent food waste by connecting surplus food from manufacturers to other businesses and charities that can use it. By ensuring excess food is sold or donated, Yume technology is helping manufacturers reduce food waste in their supply chain and meet their sustainability agenda. Yume has collaborated with Unilever, Kellogg’s, Mars Food and more, redistributing almost 8 million kilograms of surplus food and returning over $22m to leading companies.

Having proven its ability to make a real difference, the company secured $2m in seed funding in January 2024.

Image credit: https://www.yumefood.com.au/prevent-food-waste

The world’s largest commercial explosives manufacturer, Orica, has completed the biggest emissions-abatement project in the Australian chemicals sector. The manufacturer successfully abated emissions from its three nitric acid plants on Kooragang Island, near Newcastle in NSW.

For perspective, these nitric plants represent 23% of the chemicals industry’s total emissions in Australia – and Orica has now eliminated half of them. If you think about this in terms of car emissions, removing half a million tonnes of CO?equivalent is like removing 100,000 vehicles from the roads every year.

That’s no mean feat.

Unsurprisingly, Orica was recognised as the most sustainable company for impact in the AFR’s 2024 Sustainability Leaders awards.

Coles has a strong green agenda, and it’s not afraid to show it. Coles’ partnership deal with energy supplier Origin, signed in 2023, will see the companies co-invest in renewable energy and batteries at up to 100 Coles supermarkets and liquor stores across Australia over the next three years. Batteries will be installed at one-third of the stores to capture and store excess renewable electricity generated on-site. The partnership aims to help reduce each participating store’s electricity use from the grid by around 20% on average, supporting the supermarket giant to achieve its 100% renewable electricity goals by June 2025.

Coles is also focusing on the small things that make a big impact, including reducing unnecessary and problematic plastic packaging. For example, it has removed the plastic opening from Coles Own Brand Tissue products. The packaging change is set to remove 13 tonnes of plastic from circulation in one year. It has also removed plastic measuring scoops from Coles Brand and Coles Ultra laundry powders and replaced plastic bread tags with cardboard alternatives, diverting 79 tonnes of polystyrene plastic from landfill each year.

Regardless of where you are in your sustainability journey, these Australian companies provide valuable lessons and inspiration. Every business has a critical role to play, and by learning from these companies, you can positively contribute to the global sustainability movement.

Inspired to take action? Here’s how you can reduce waste in your coding and labelling process and learn why you should use sustainable packaging according to Woolworths.