Aug 20, 2024 by Mark Dingley

As consumers deal with the cost-of-living crisis, manufacturers are dealing with their own situation: the cost of doing business.

Manufacturers are grappling with inflation, high energy and materials costs, soaring freight and transport bills, rising wages and flagging consumer demand simultaneously.

In fact, confectionery, snack foods and pet-food maker Mars, in an interview in “The Australian” newspaper, labelled Australia one of the most expensive countries it operates in from its global network of factories.

So, what can you do to weather the storm?

Here are 7 strategies for manufacturers to deal with the cost-of-doing-business crisis and keep their businesses thriving.

To contain and ideally reduce costs, every manufacturer needs to take steps to create more efficient manufacturing. That’s where automation can help.

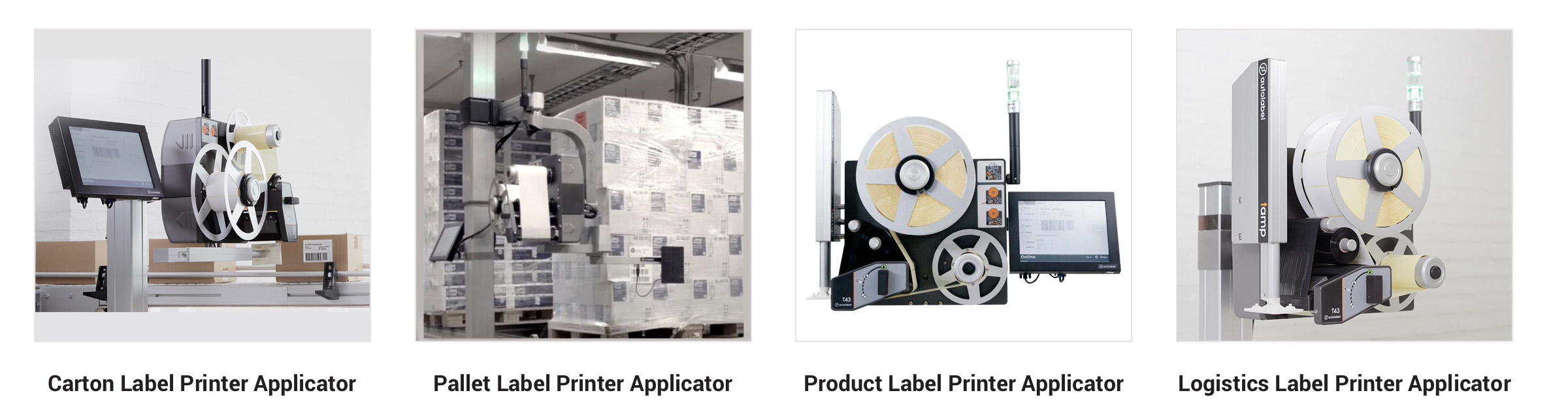

The biggest value automation brings is process improvement and cost reduction by simplifying, reducing or eliminating manual tasks. For example, rather than using humans to apply labels to products, a Label Printer Applicator (LPA) frees up your team for other value-adding areas while improving productivity and accuracy.

Automation can also improve quality and reduce waste, which will help save money.

Take AusFresh. The company used a highly manual process to label cartons by hand. One person printed up to 7,000 labels daily while standing at the printer to remove printed rolls and wind them manually. They passed the labels to another operator, who used a date gun to apply the batch code and use-by date before applying two labels to each box. Not only was this a highly resource-intensive process, but it had a high risk of human error, meaning more waste. Implementing an integrated carton print-and-apply system helped them improve productivity and quality.

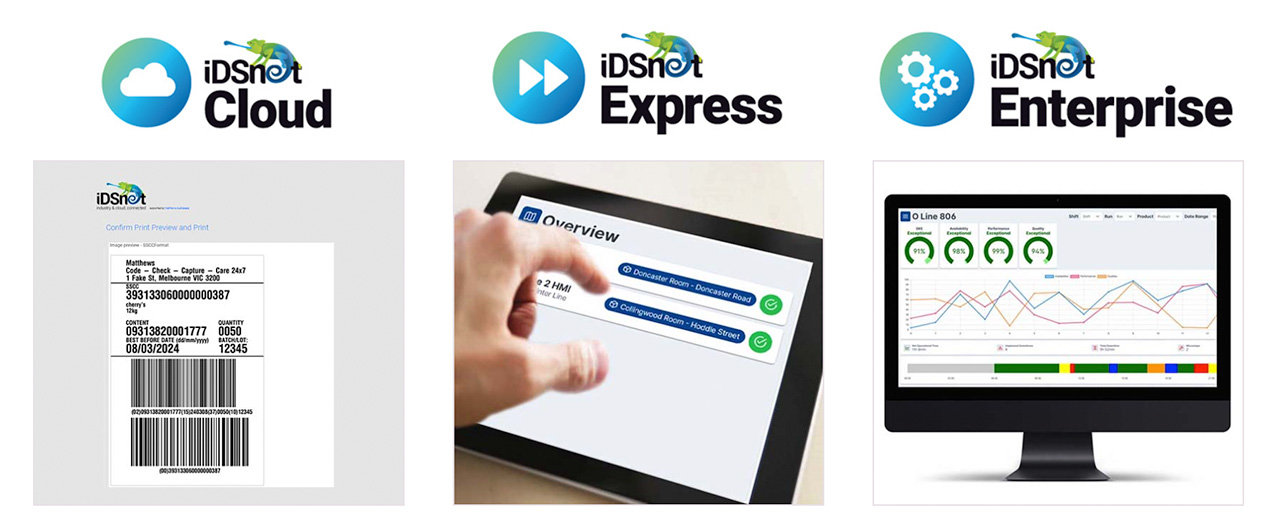

Automation can also give you access to data that can be used to improve processes, find operational efficiencies, improve quality assurance and even transform business models. Making decisions based on solid data is more critical than ever: as the saying goes, “the numbers don't lie”. In an unstable economic and consumer landscape, your data remains reliable and crucial to making informed business decisions.

Line-performance software, such as Matthews iDSnet, allows you to collect data from equipment and display it on live dashboards. Managers can use the insights to pinpoint stoppages, bottlenecks and issues and improve their Overall Equipment Effectiveness (OEE).

It’s time to get serious about reducing energy costs. Energy use accounts for at least 15% of the total operational costs in a food & beverage manufacturing business. So, if you can take control of your energy costs, you can take control of your costs – full stop.

Examine where and how your business uses energy to identify how you can save energy costs. This is where automation can help. Some platforms can provide insights into energy use throughout your operations, giving you the visibility to make decisions.

Another method is metering and monitoring. This helps you better understand energy and material flows, identify any excess energy use, and evaluate the costs and benefits of potential equipment upgrades. By acting on low-cost quick wins, you can typically get a payback on investment in under two years, according to energy.gov.au.

Detailed meter data can also help diagnose problems before they lead to high energy consumption or component failure. For example, excessive energy consumption outside operational times can indicate faulty controls or switches.

Meter data can also help you build the case for equipment upgrades, whether you’re applying for finance or government grants.

Are you waiting until your equipment breaks down before making repairs? If so, you’re adding unnecessary costs and inefficiencies to your business.

Not only do you have to pay the premium for an emergency repair call-out, but you also have the costs of unplanned productivity loss and wasted resources. Unplanned downtime can also lead to delays, which means unhappy customers and a direct hit to your bottom line.

The cost of equipment failures can be high, but you could also lose money daily if your equipment runs at sub-optimal levels.

Preventive maintenance programs can detect potential problems before they become severe and ensure your equipment runs optimally. Running equipment at optimal levels can also provide significant energy savings. Machines running more efficiently use less energy and resources, extending the overall life of your equipment and critical components while improving production quality and reducing waste costs.

Look for unique growth opportunities arising from the cost-of-living crisis—they could provide a much-needed lifeline.

One of these is the rise of private labels.

Consumers can’t get enough private labels to save money. To tap into this demand, retailers increasingly seek to expand their private-label product ranges and enter new categories.

For manufacturers, this could mean a significant boost in revenue. A study by McKinsey & Company found that manufacturers who successfully increase their private-label penetration have a distinct advantage in overall gross margin.

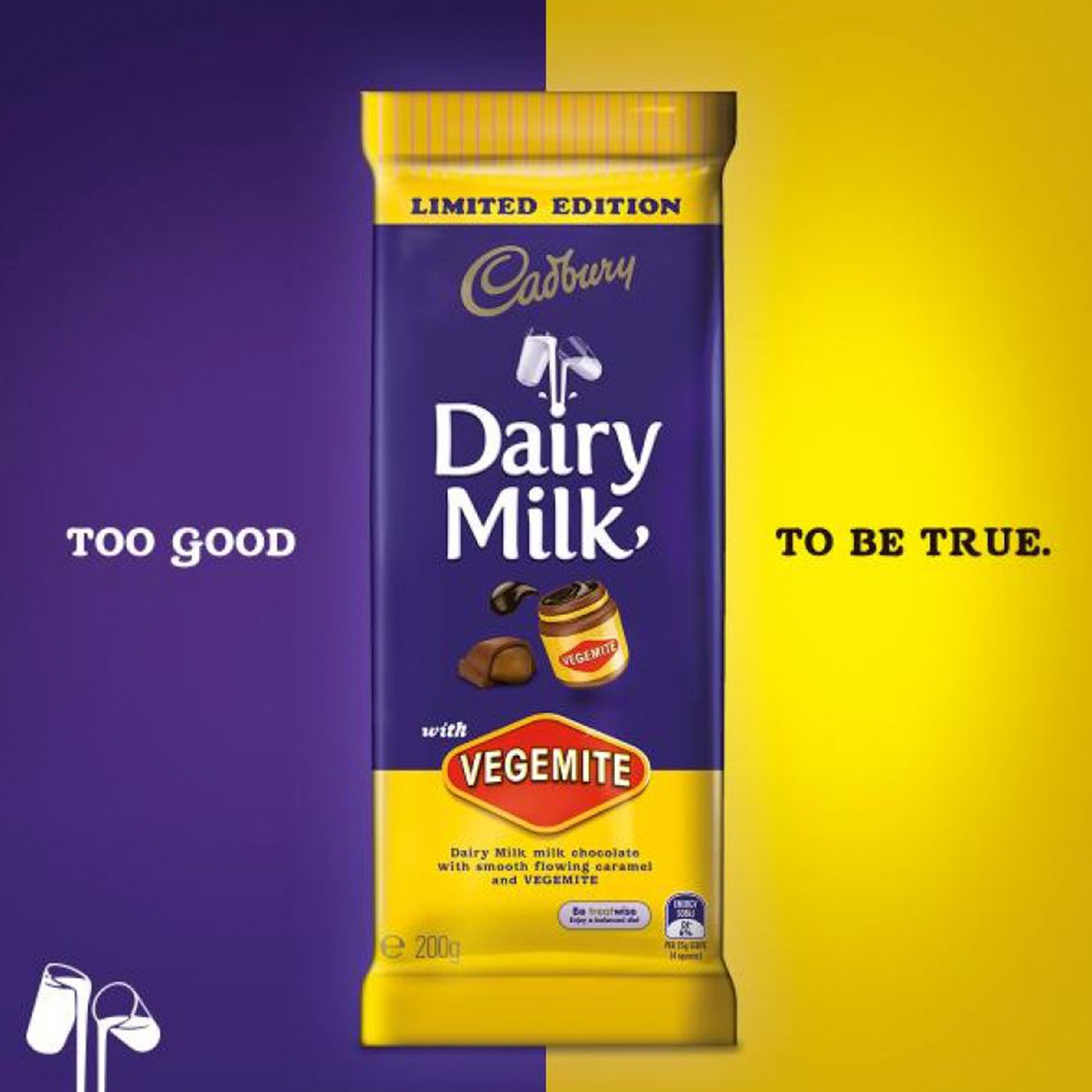

Growing your customer base is challenging in today’s marketplace, but it’s not impossible. You simply need to team up with other brands.

Brand partnerships not only broaden your audience but also inspire new growth opportunities. Joining forces means you share the benefits of increased brand awareness, exposure to a broader audience, and more sales. The trick is to have a goal and find the right brand to help you achieve it.

Get inspiration in our list of the best food brand collaborations.

Many support programs offered by the government and other organisations are available to help manufacturers in these challenging times. Take some time to research and find relevant grants for your business.

Here are some examples:

Lastly, it’s important to remember to look after your mental health: as it’s just as crucial as managing your business.

Financial pressures are a significant source of mental stress for business owners, but you don’t have to suffer alone. The recent Federal Budget allocated $10.8 million to deliver tailored, free, and confidential financial and mental well-being support for small business owners – and it can’t come too soon.

In the meantime, there are lots of resources to lean on, including:

As Albert Einstein said: "Life is like riding a bicycle. To keep your balance, you must keep moving." By proactively taking steps to reduce costs and increase efficiency, manufacturers cannot just survive, but position their business to thrive in a volatile economic landscape.

Take your first step today – find out more about how automating your labelling and coding processes can improve efficiencies, reduce waste, and save costs. Talk to our experts.